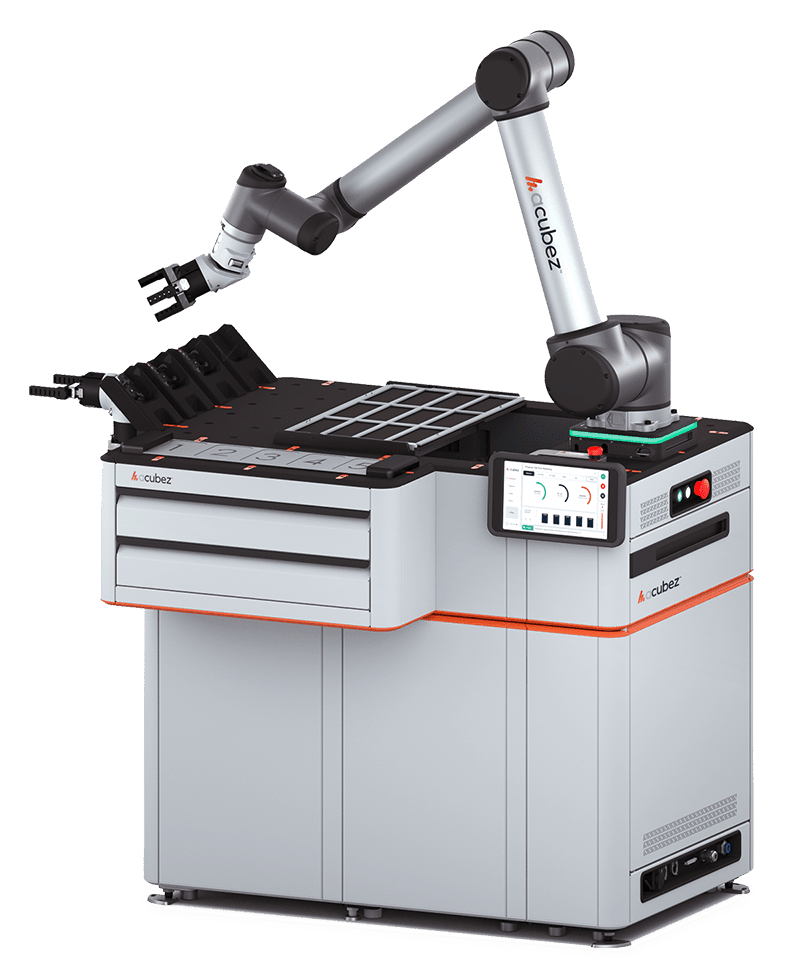

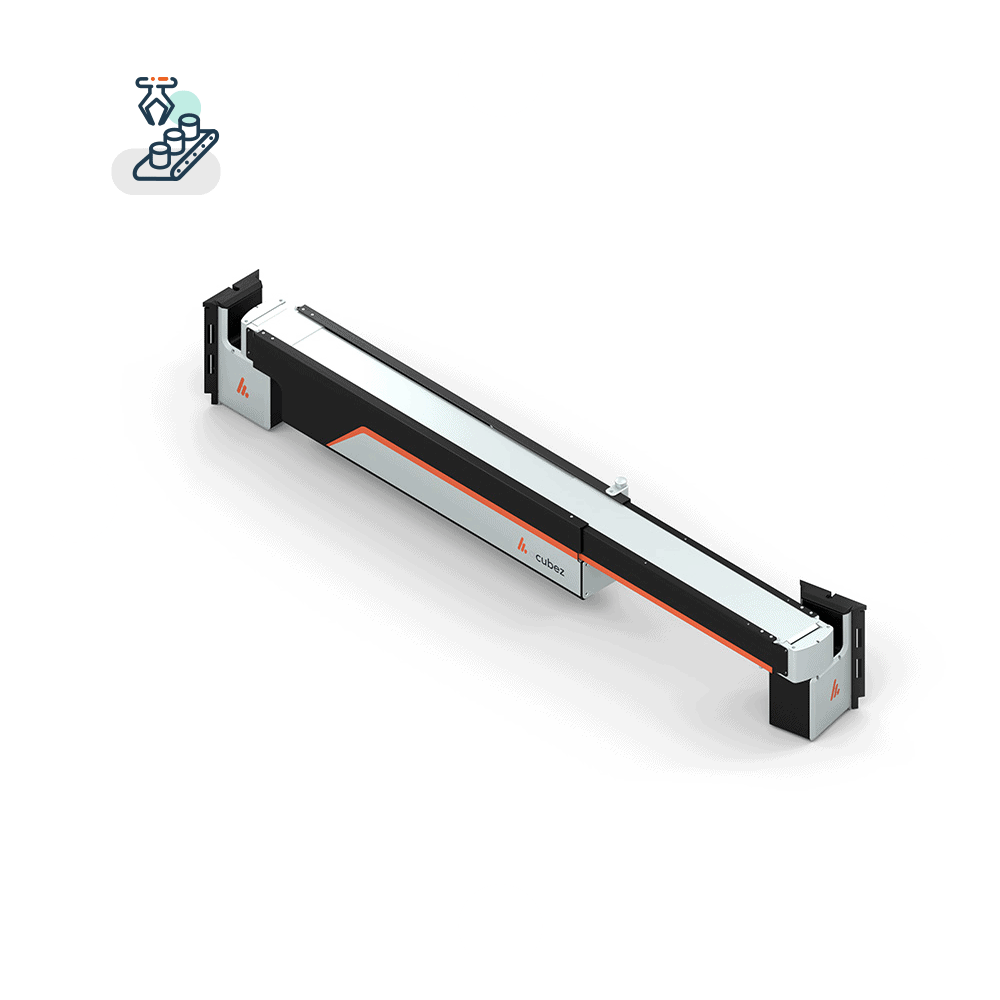

The acubez™ 800 is our standard, most-economic, compact, manufacturing configuration for machine tending automation. This cost-effective and flexible plug-and-play automation solution increases quality and productivity of exisiting CNC machines. The acubez™ machine tending robots have a compact footprint of only 850x650mm, and are the perfect starter configuration to automate CNC lathe, milling and mill-turning, laser marking and other pick and place applications.

Maximize Efficiency with Machine Tending Robots

The acubez™ 800 configuration is the ideal fit for low-capacity workload requirements. This robotic machine tending platform allows uninterrupted loading and unloading of your CNC machines with fast automation set up times.

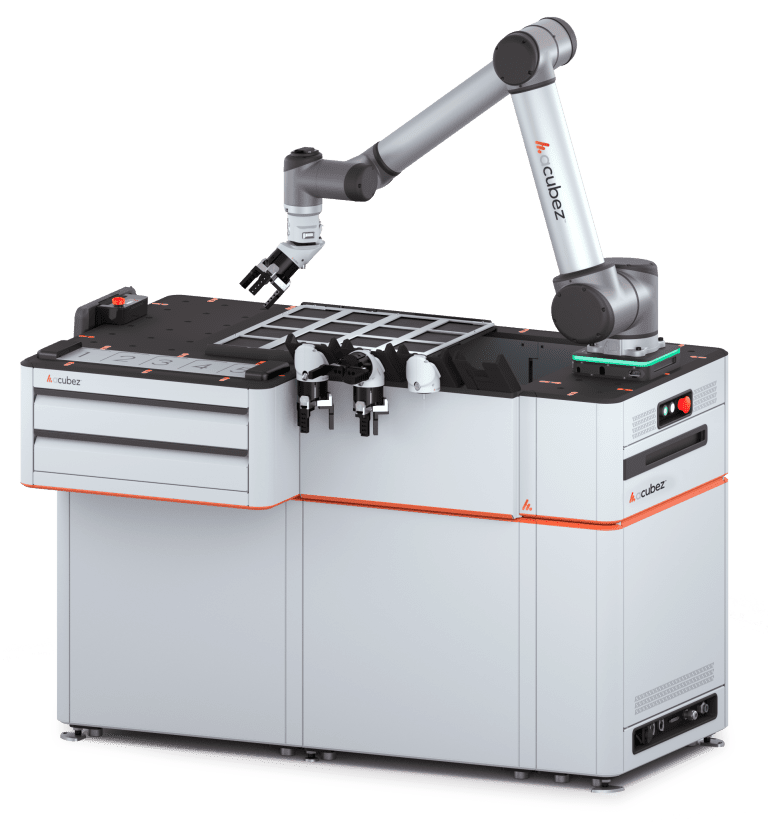

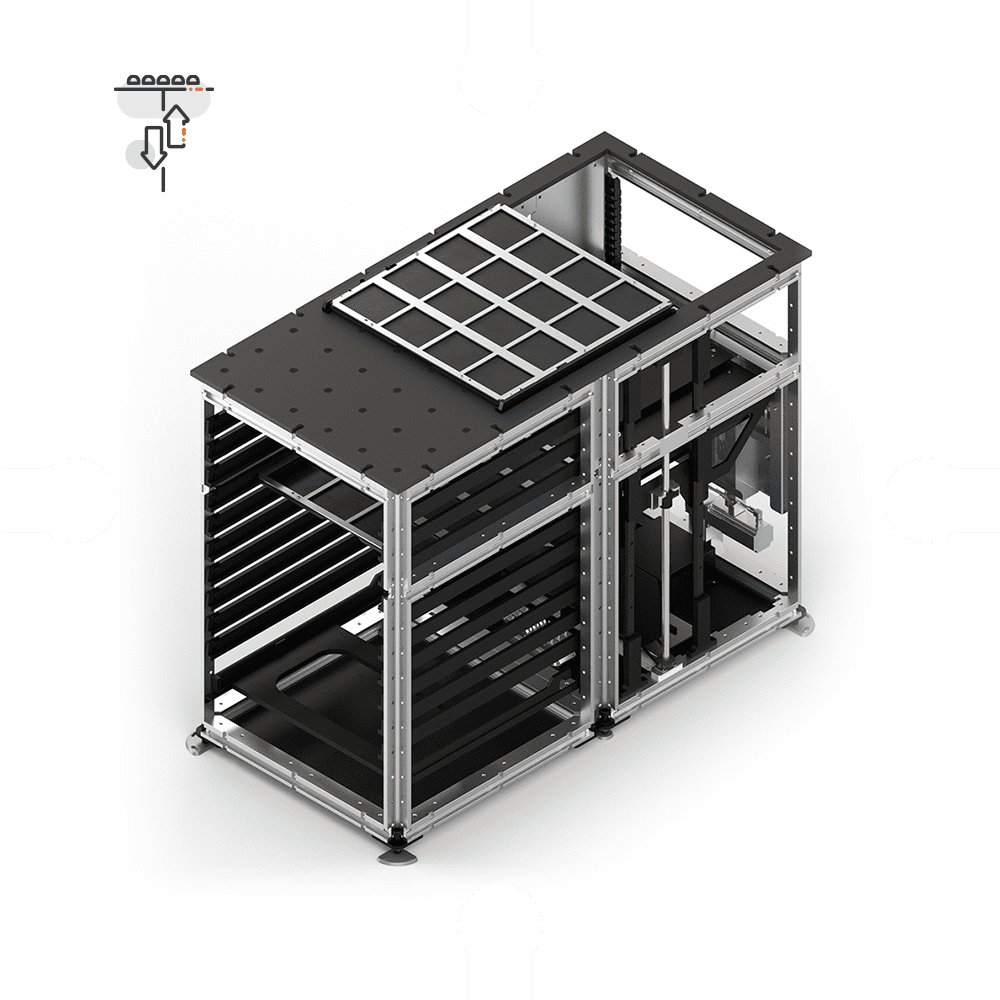

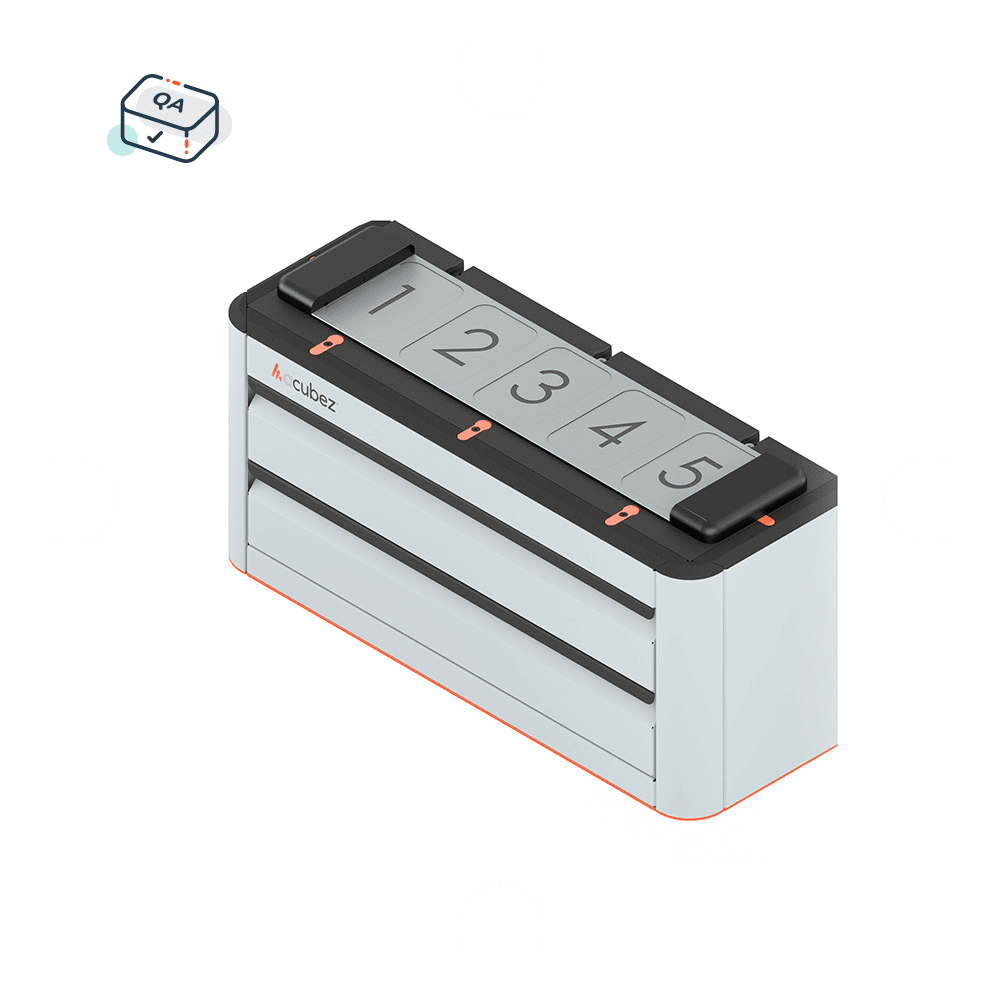

For easy scalability, the acubez™ 800+ comes fully equipped with the StorageCube upgraded from the 800, which only starts with the TableCube, allowing you to store manually finished workpieces through automated manufacturing processes.

- Fits best for small automated manufacturing lots

- Automate CNC Lathe, laser marking, CMM machines and more