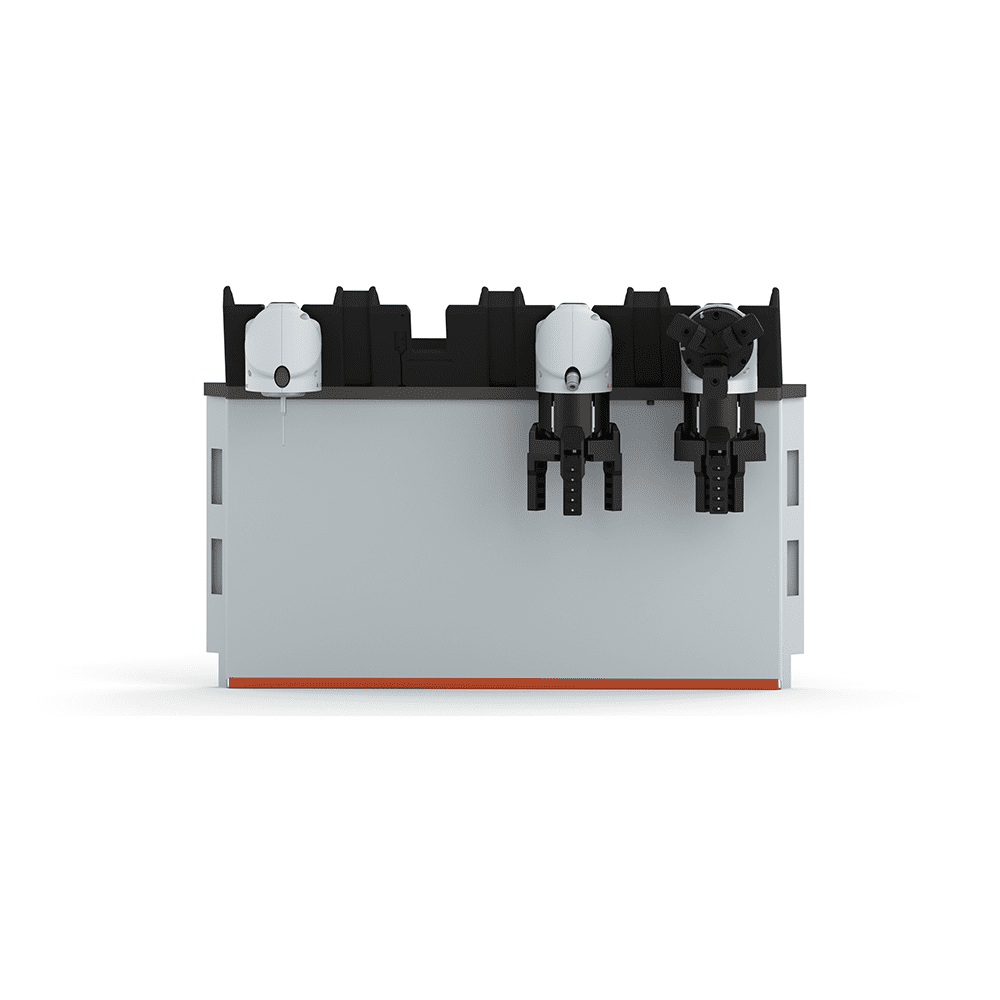

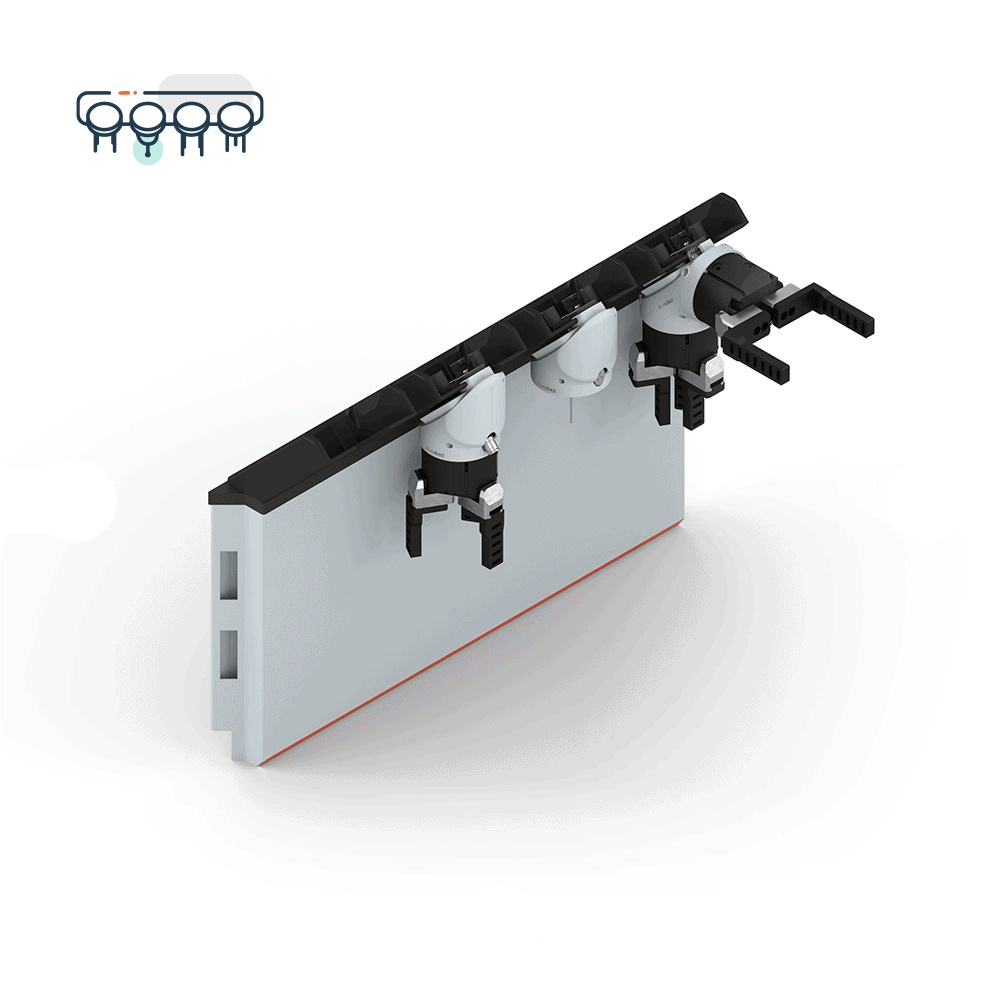

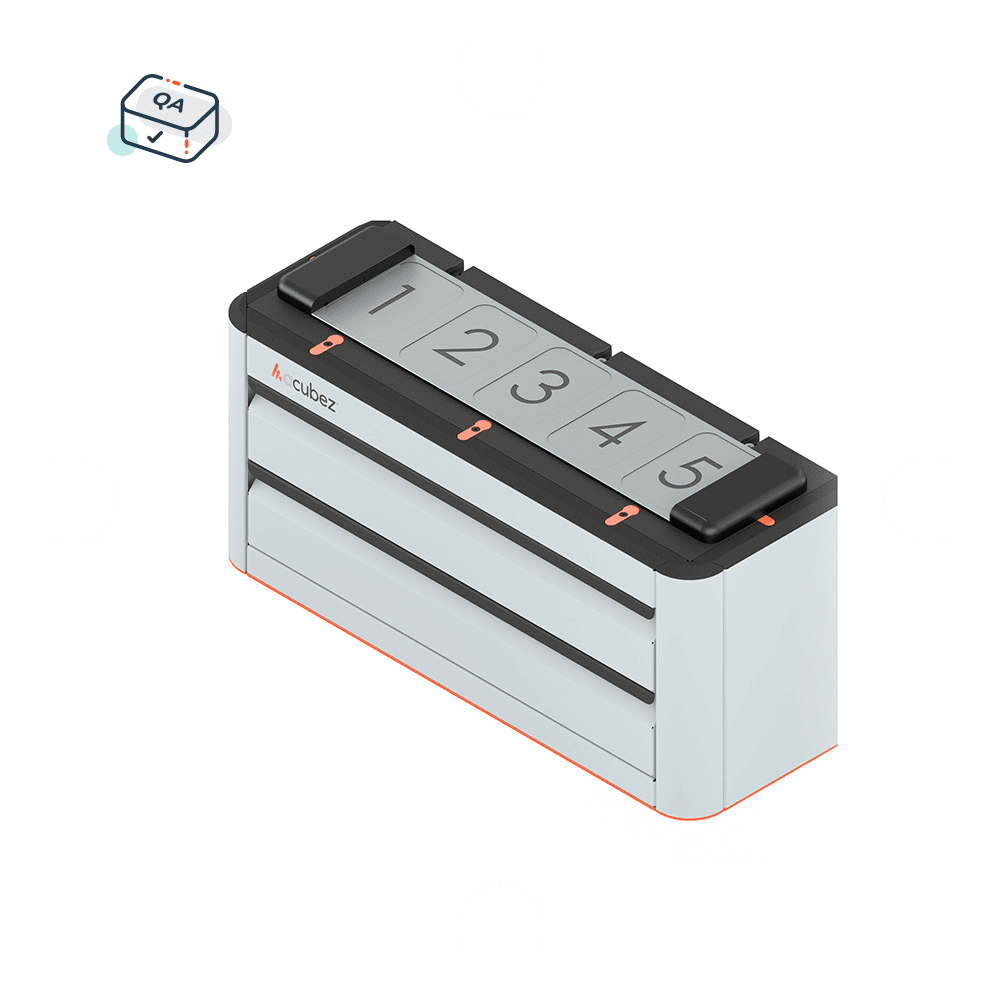

GripperCube

The GripperCube is an innovative and smart gripper holding rack that recognizes and holds up to 4 acubez™ grippers from its wide selection of acubez™ EOATs . The robot tool changer switches quickly and easily between the different end effectors to fit the size and make of raw materials and final workpieces.

Automatic robot tool changer

- Rests easily on peripheral edge of the platform

- Enables utilization of multiple types end-of-arm tooling (EOAT) during system operation, maximizing flexibility

- Grow as you go – add parallel grippers, vacuum grippers and more