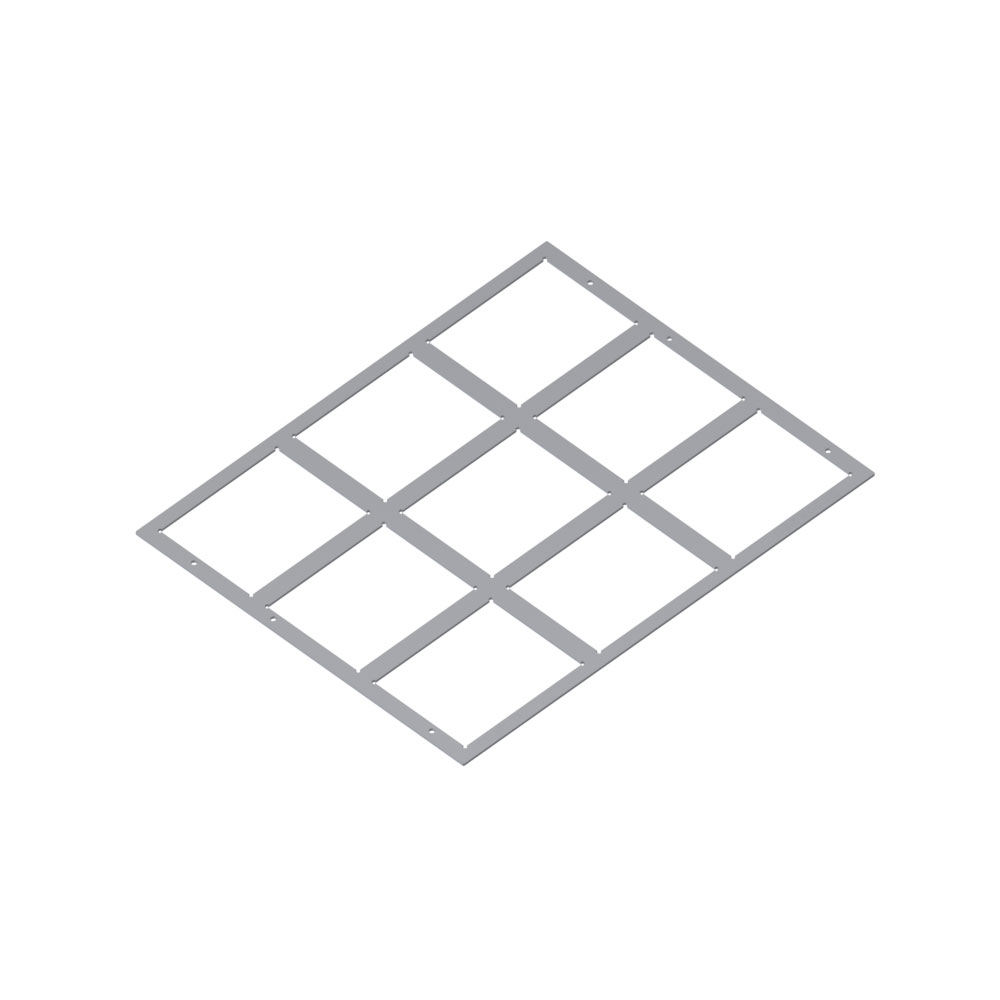

The acubez 1000 configuration is an excellent fit for medium-capacity workloads. With a base slightly larger than the 800 configuration, the 1000 platform allows for extended capacity with the ability to handle multiple trays, while providing a compact footprint of 1050x650mm. This high-efficiency, modular configuration offers uninterrupted loading and unloading operations by the automated processes of StorageCube 400 and LiftCube 400. It allows to scale later with a wide variety of modular cubes and add-ons.

The modular, “LEGO-like” concept of the acubez™ automation solution allows manufacturers to keep up with ever-changing demands!

Maximize your return on investment: automate with lower risk, lower cost, quick deployment, higher productivity and faster ROI

Within minutes any CNC machine operator can set up the automated machine tending processes for accurate operation and highly complex designs and positioning requirements.

Copyright ©2024, Acubez Modular Automation Ltd.