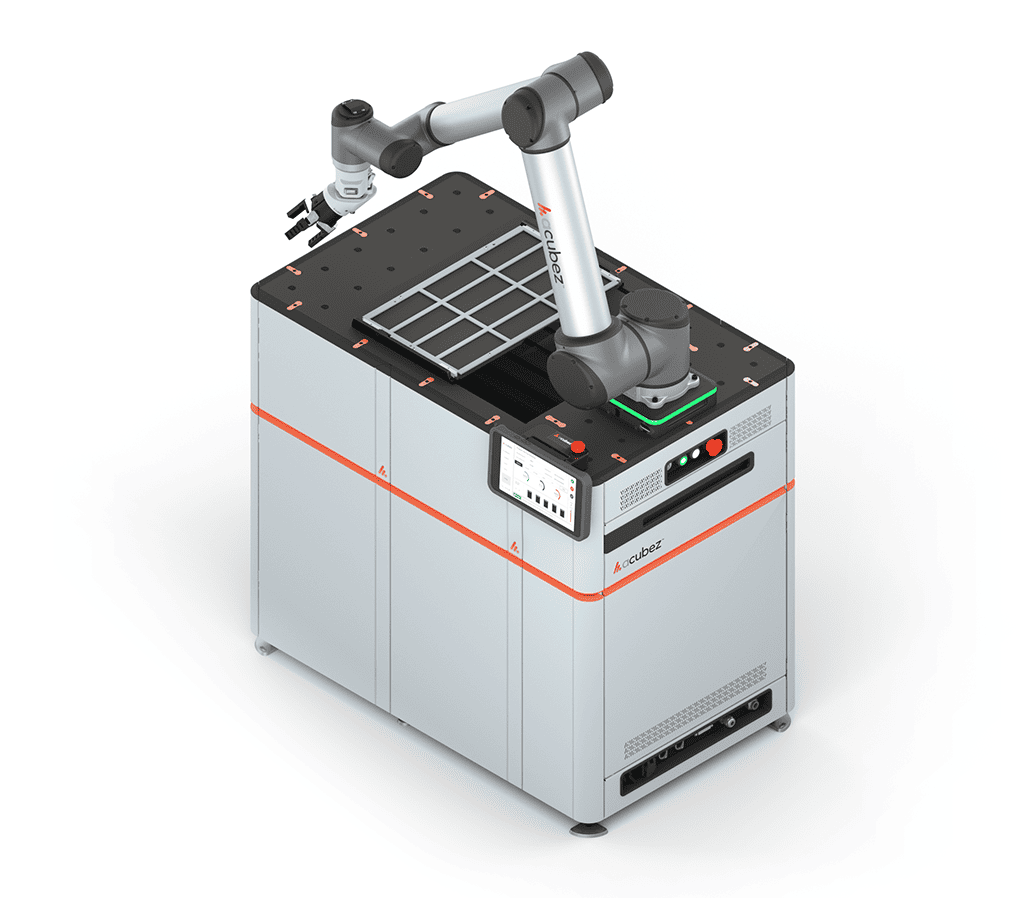

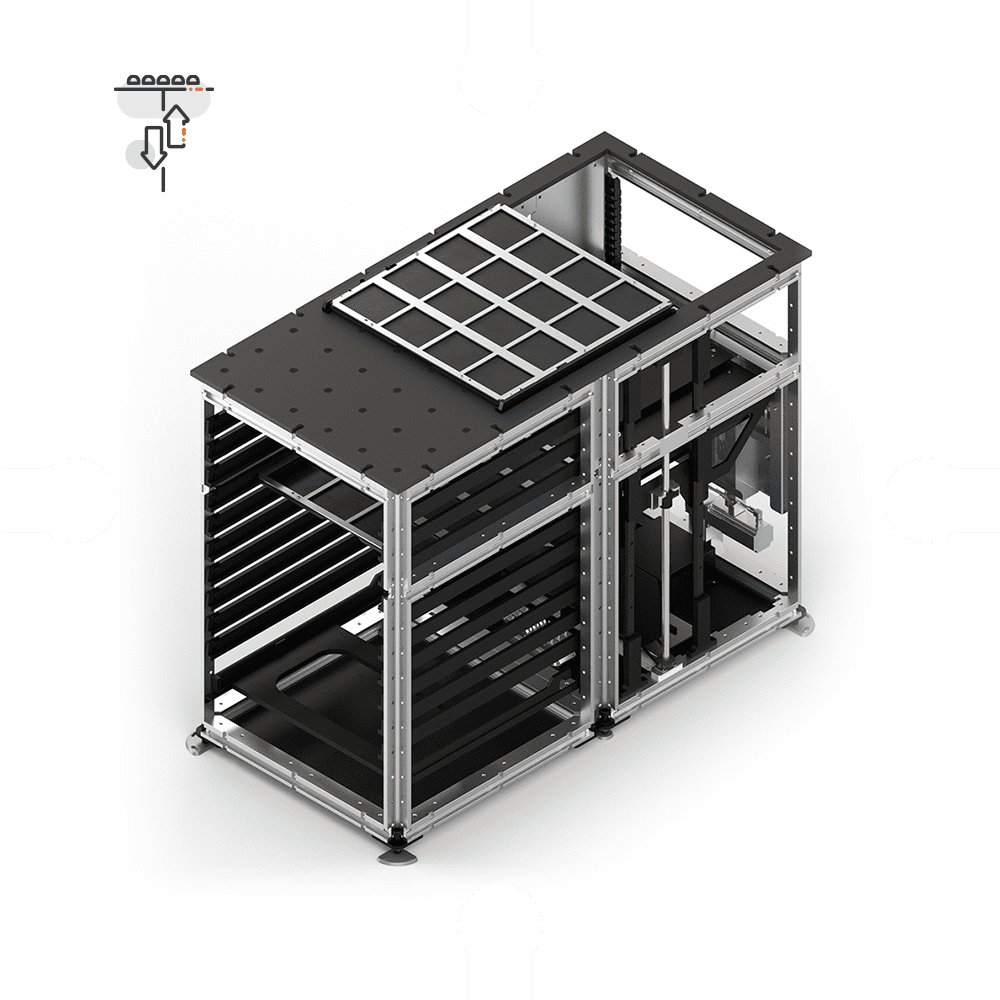

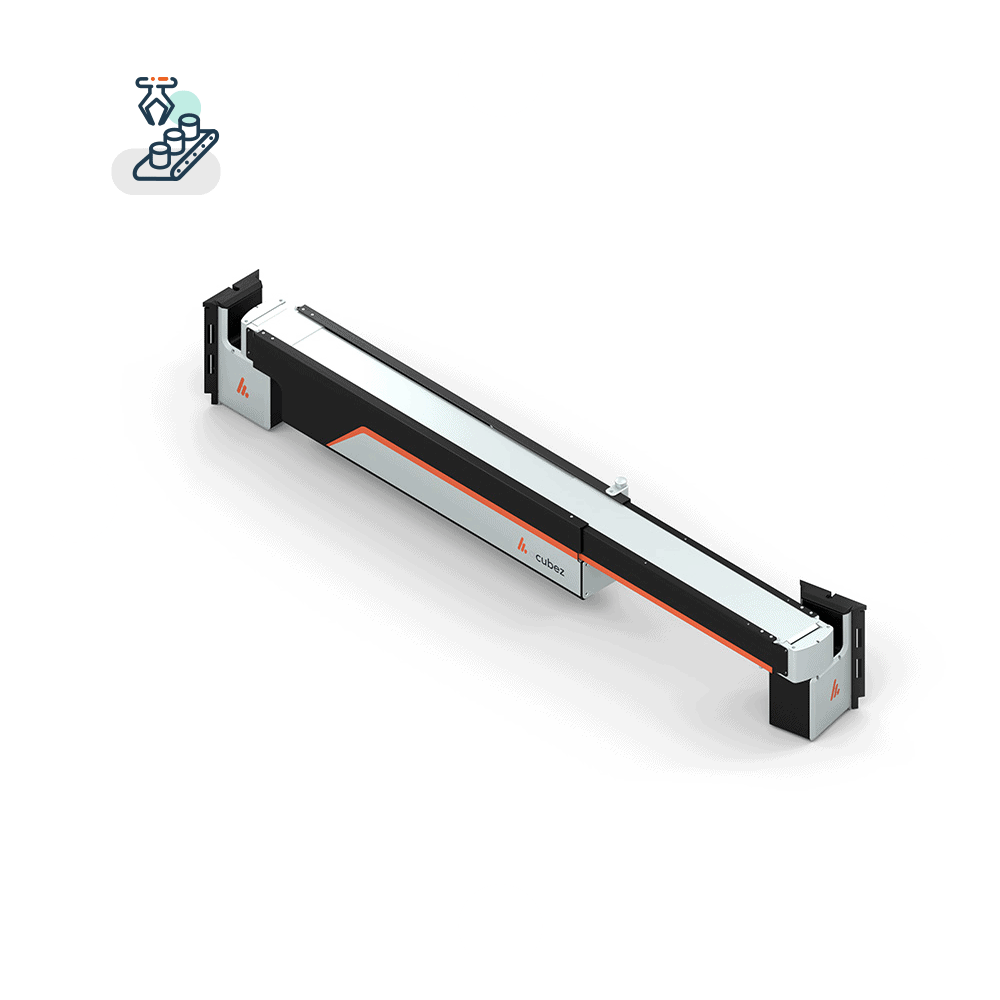

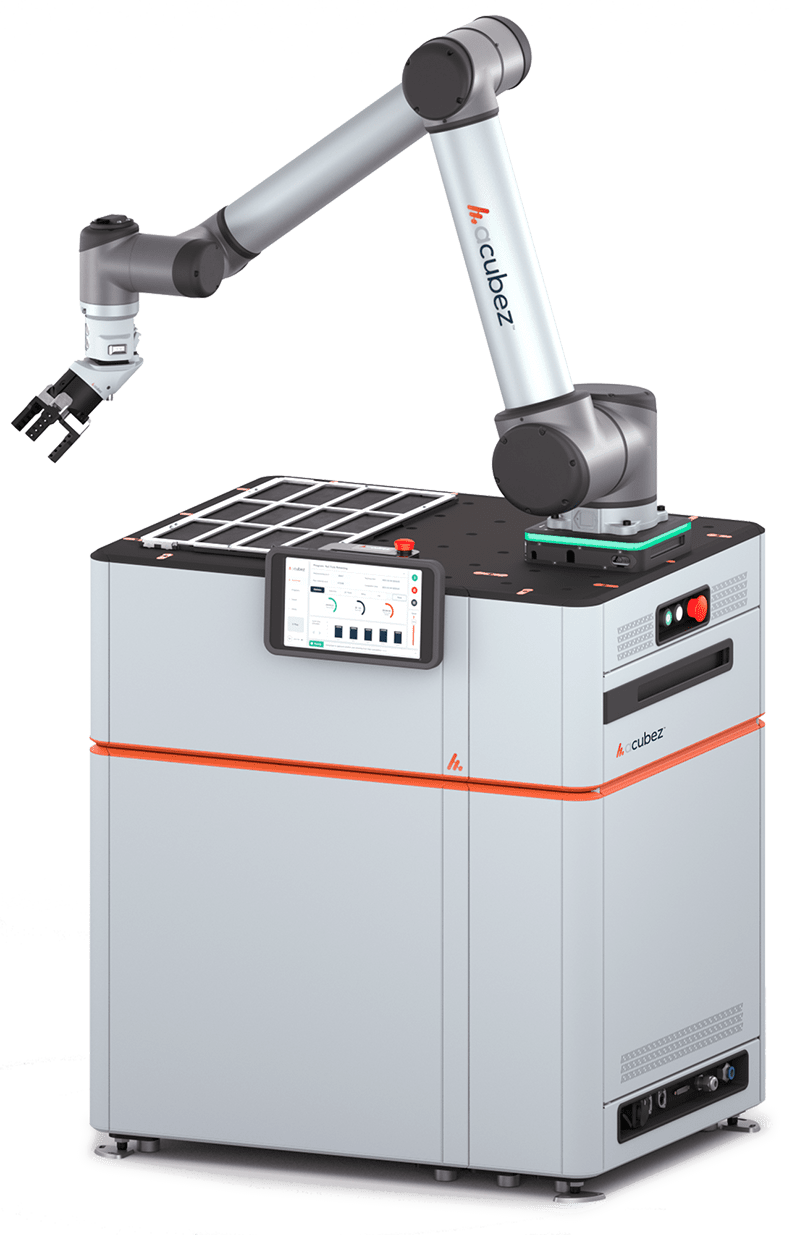

The acubez™ 1000, a modular machine tending automation solution, is an excellent fit for medium-capacity manufacturing workloads. With a base slightly larger than the 800 configuration, the 1000 automation platform allows for extended capacity with the ability to handle multiple trays.

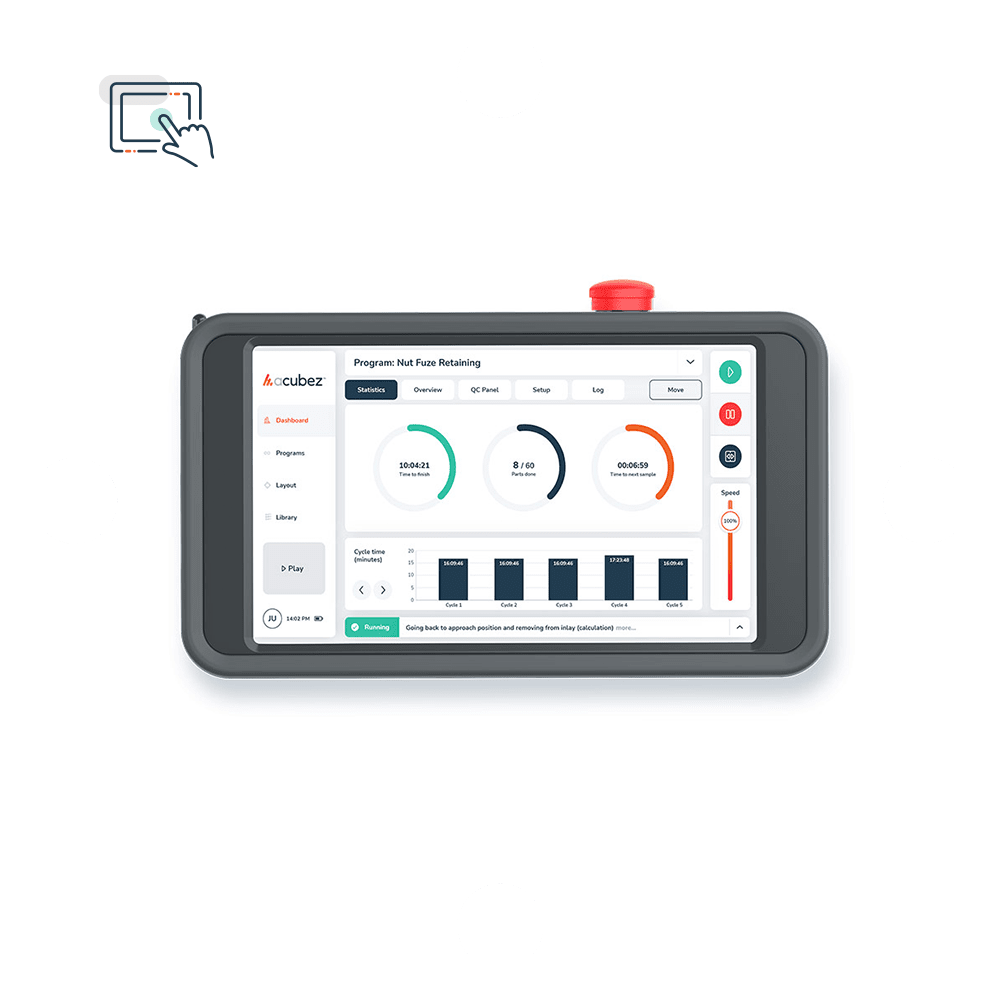

Robotic machine tending made easy

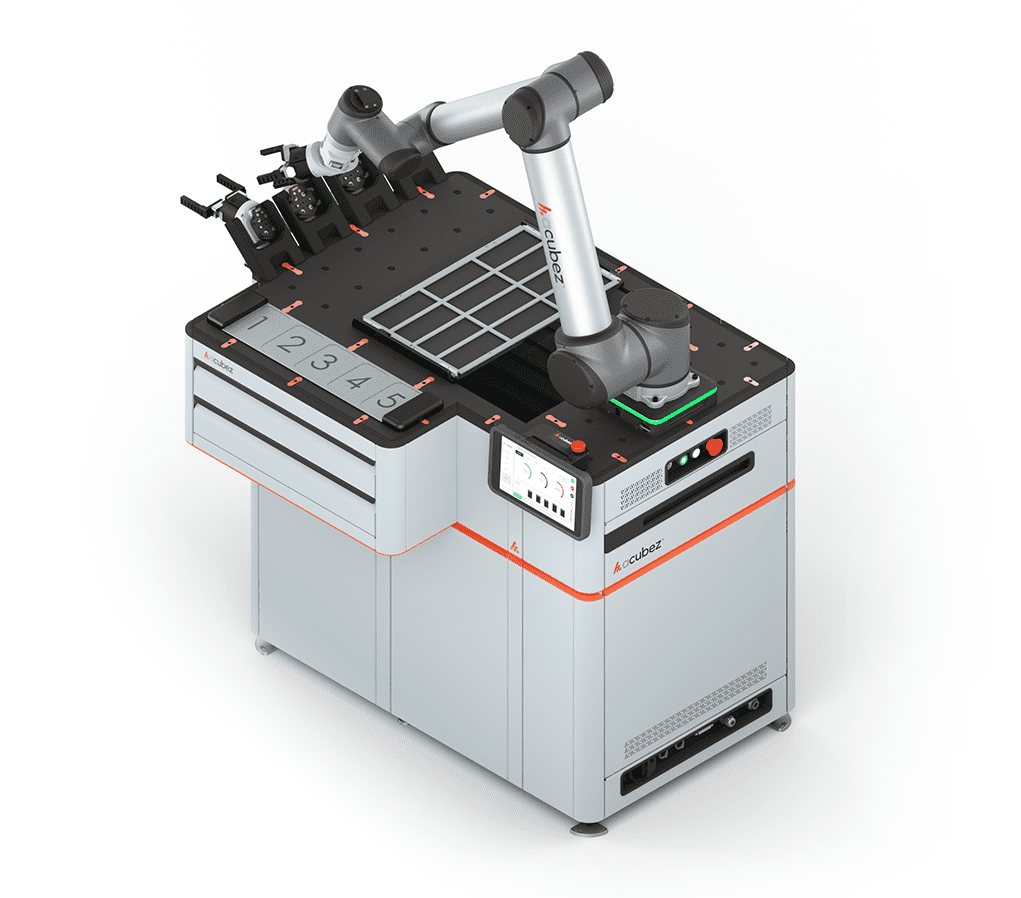

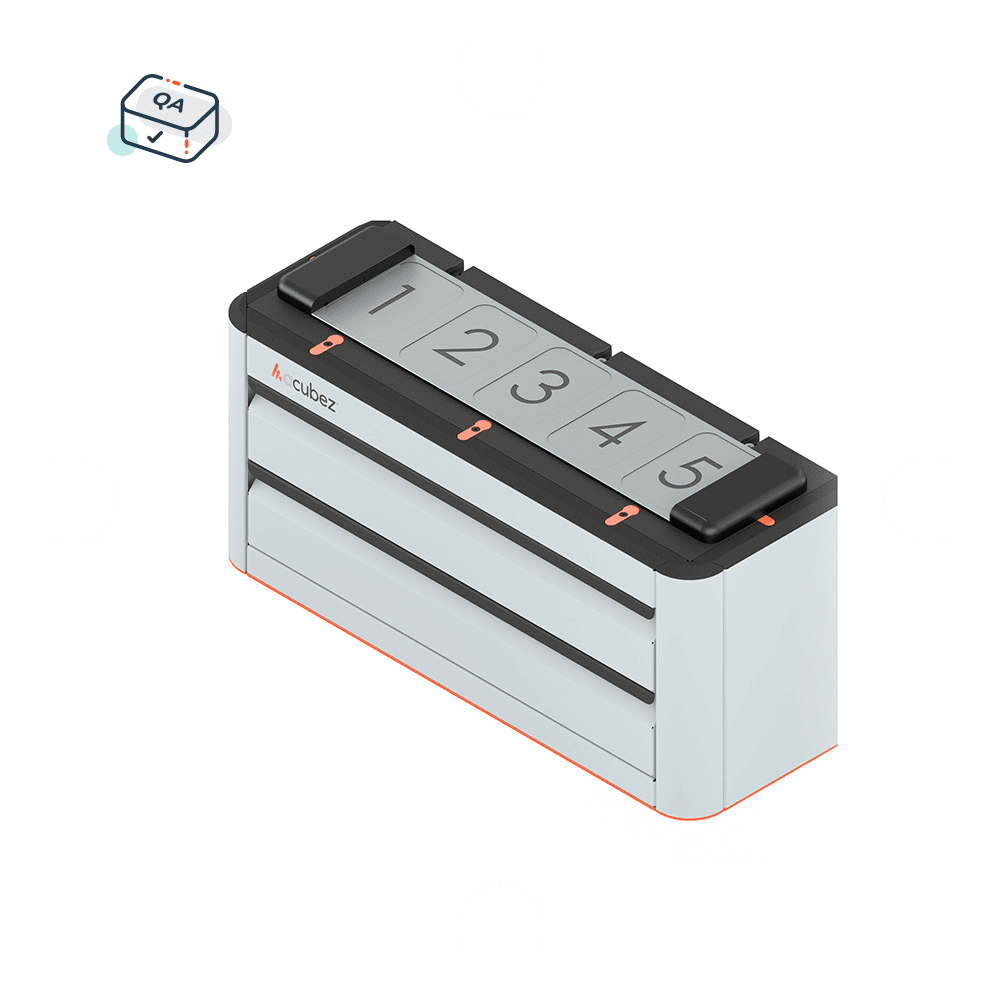

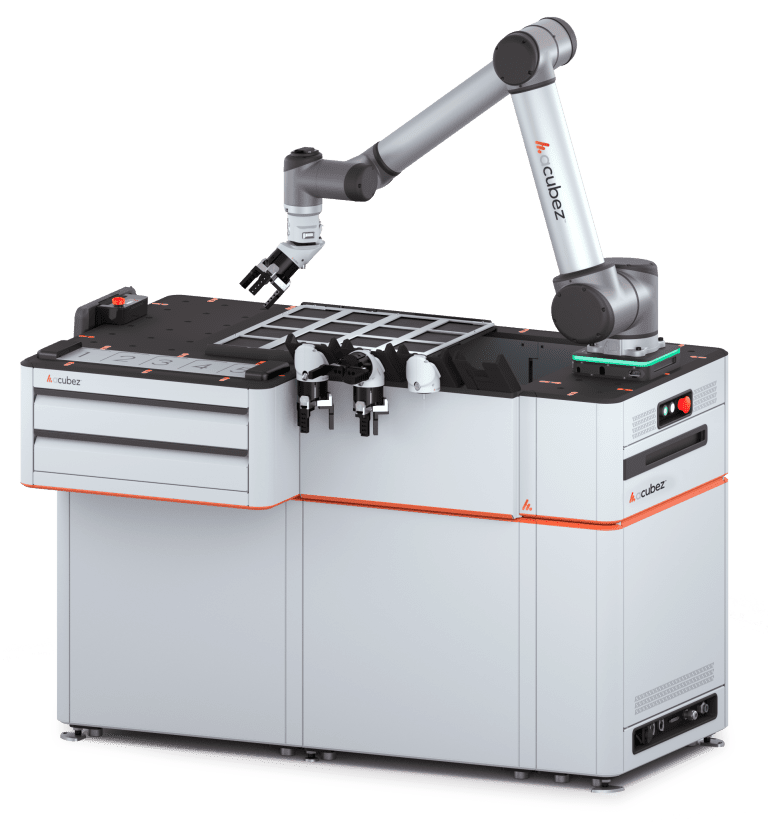

The acubez™ 1000+ automation platform further increases flexibility and control of the acubez™ 1000 standard configuration with the inclusion of the QACube and GripperCube.

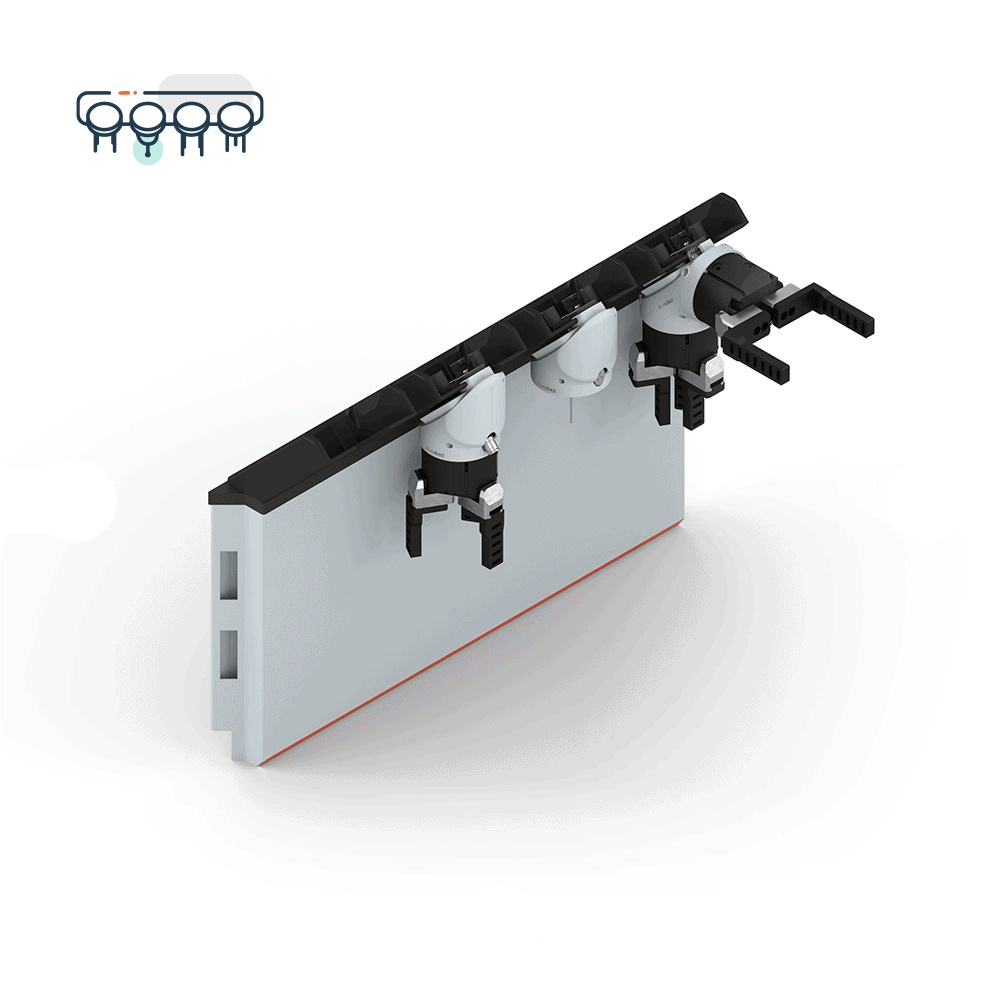

Providing even greater versatility, the acubez™ Grippers and fingers, connected to the cobot arm allow the automatic CNC machine to work with a wide variety of raw materials.Maximize your CNC machine up-time

- Fits best for medium size parts and manufacturing lots

- More than 1,200 production hours added annually to each cobot-tended CNC machine

- Future-proof investment: modular and flexible