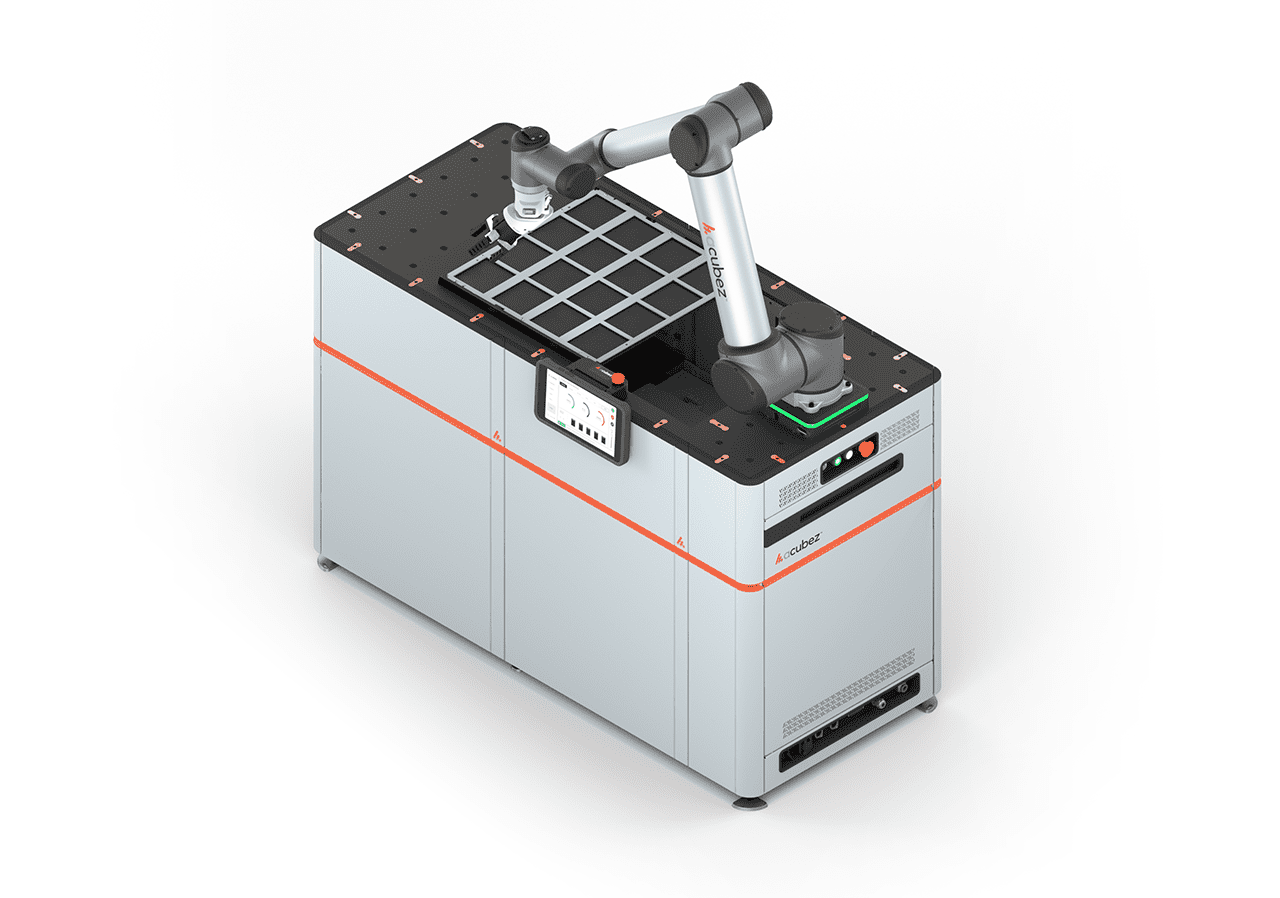

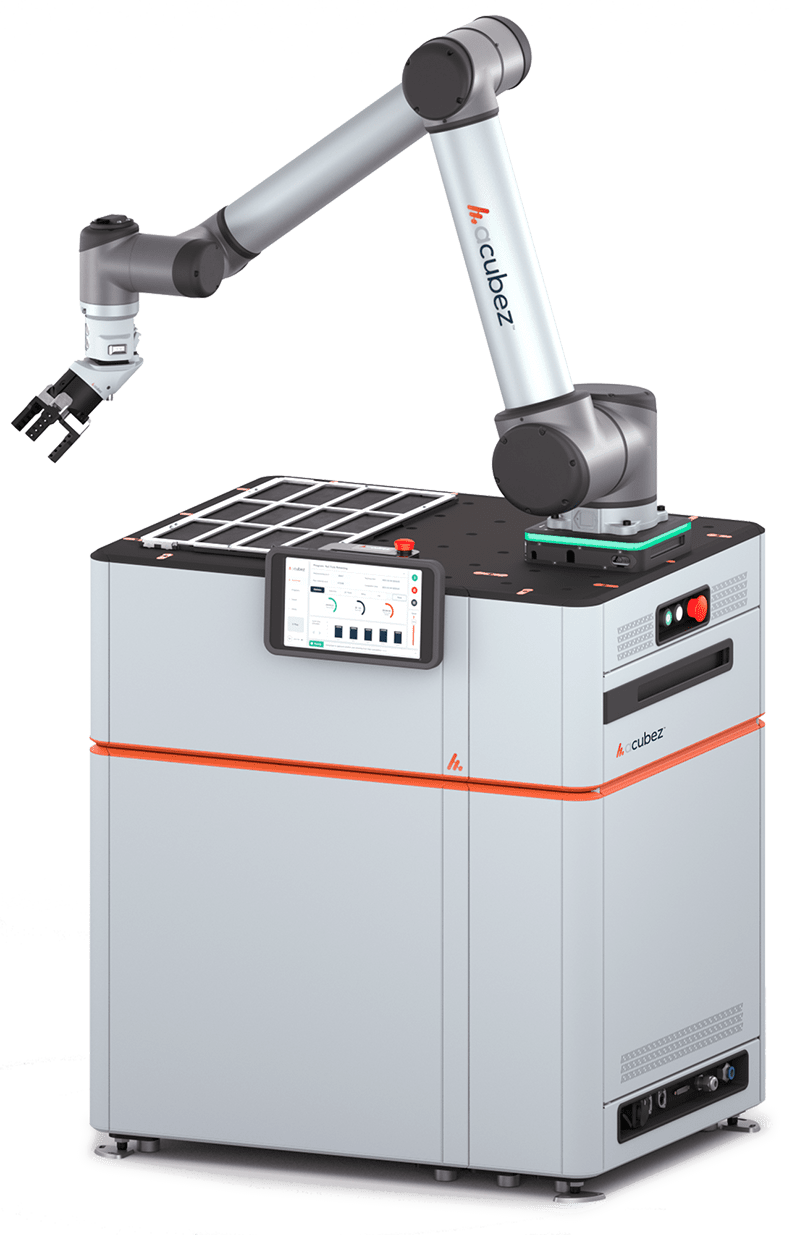

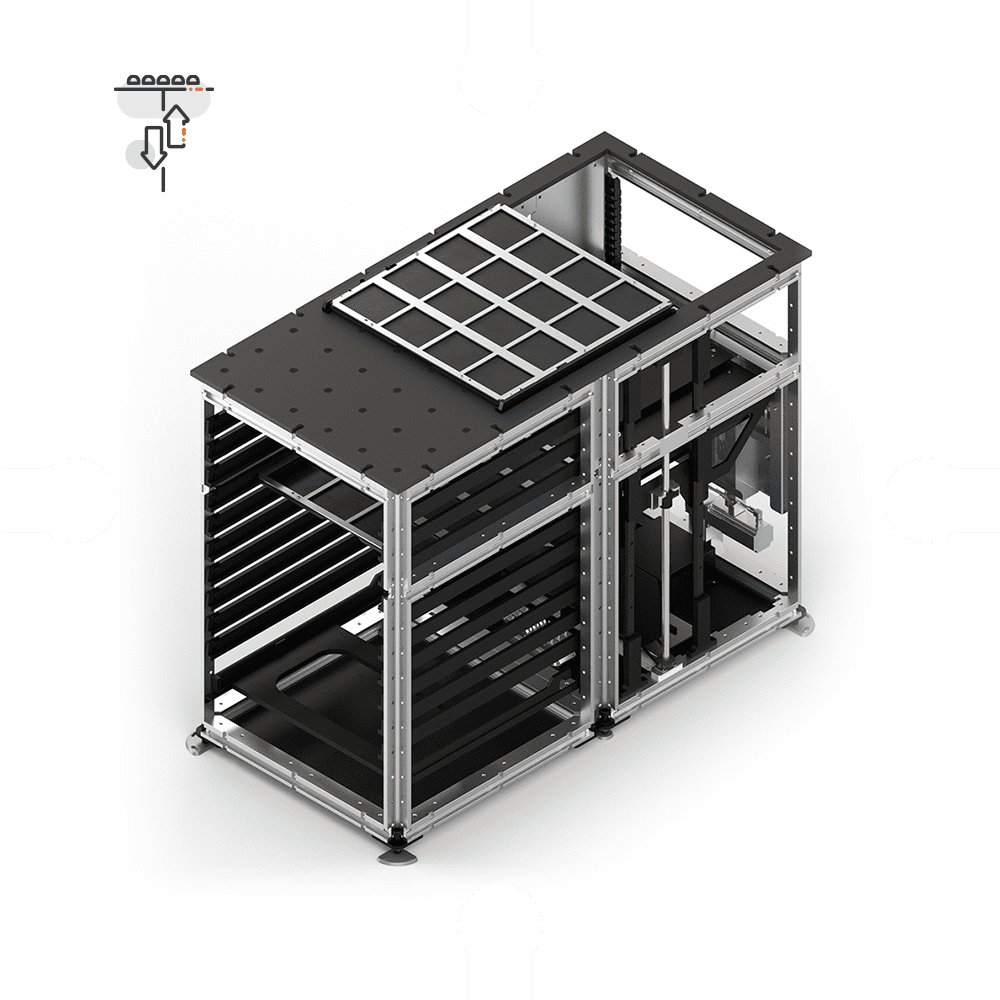

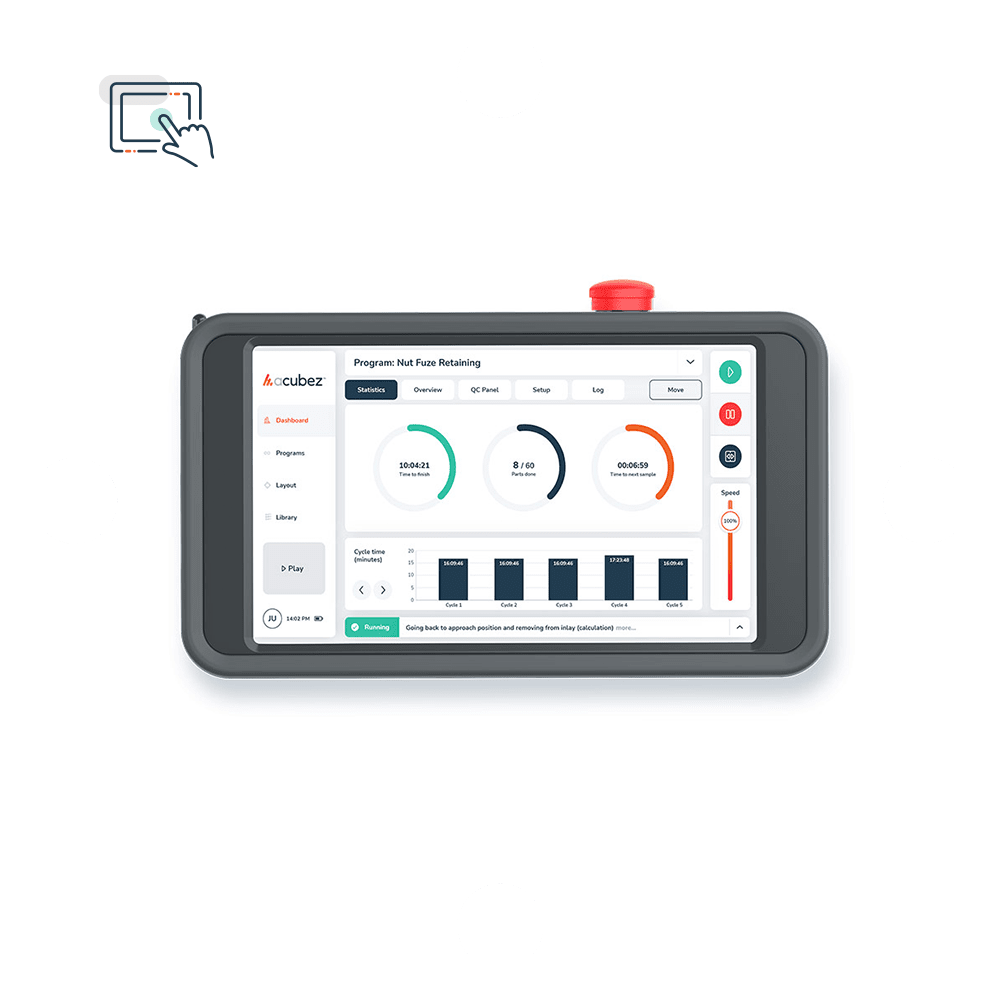

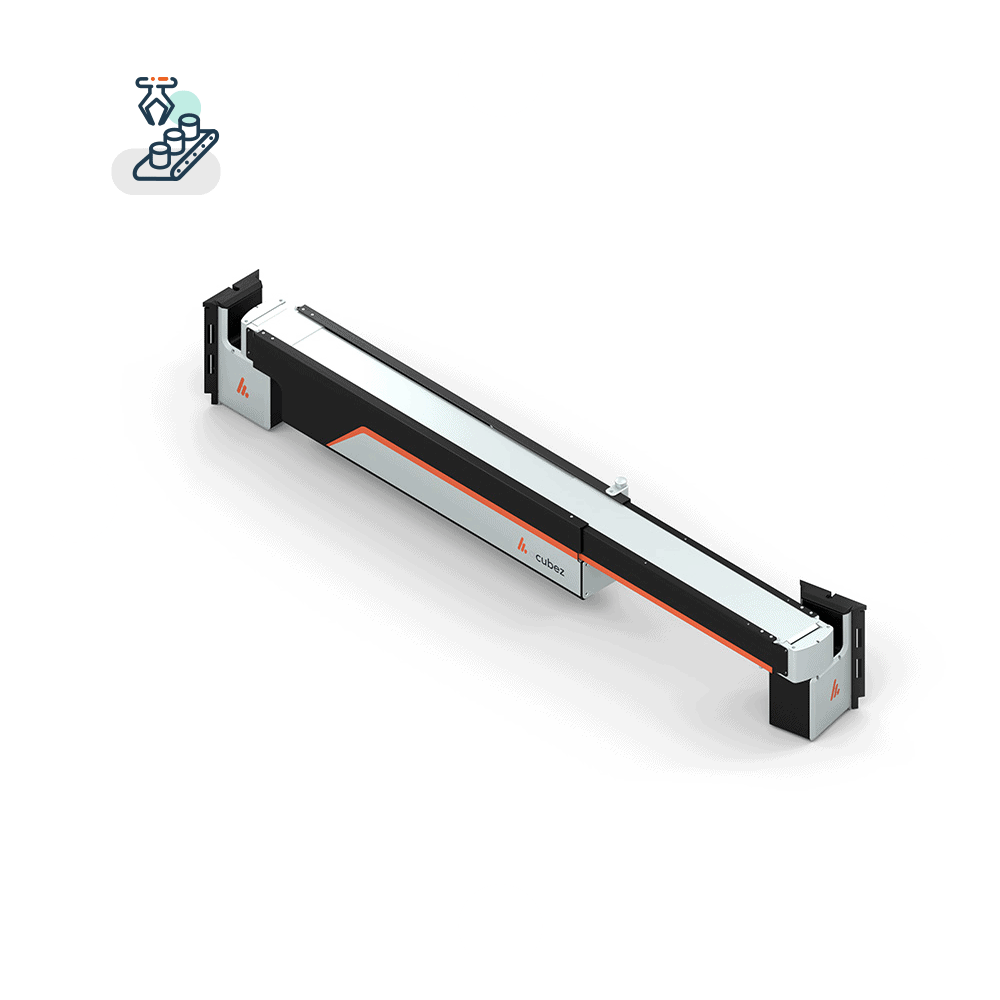

The acubez™ 1400 automation platform is manufacturer’s ideal modular solution. Cobot Automation for machine tending tasks, especially high-mix, high-volume production processes increases your existing machine’s efficiency dramatically.

End-to-End Solution for Cobot Automation

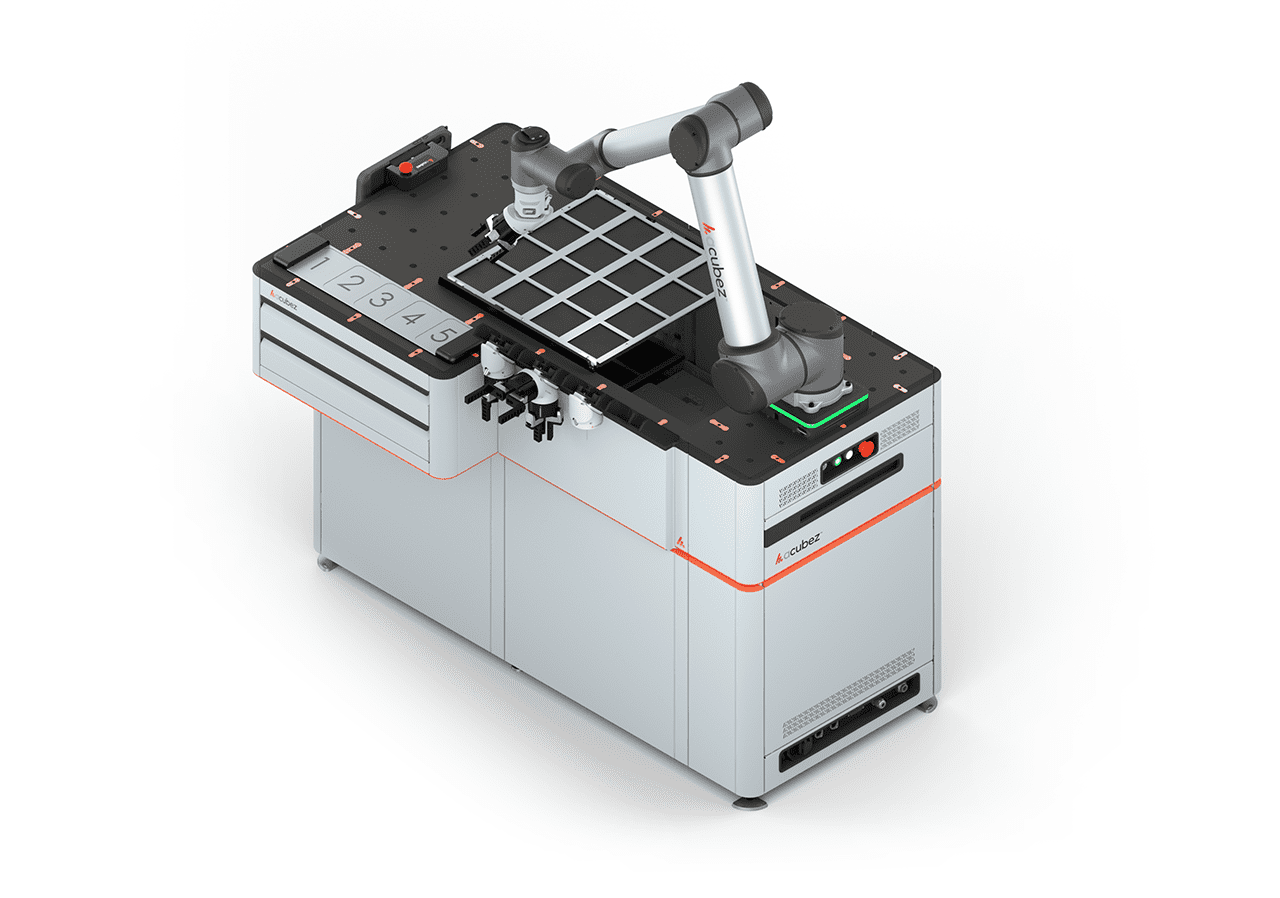

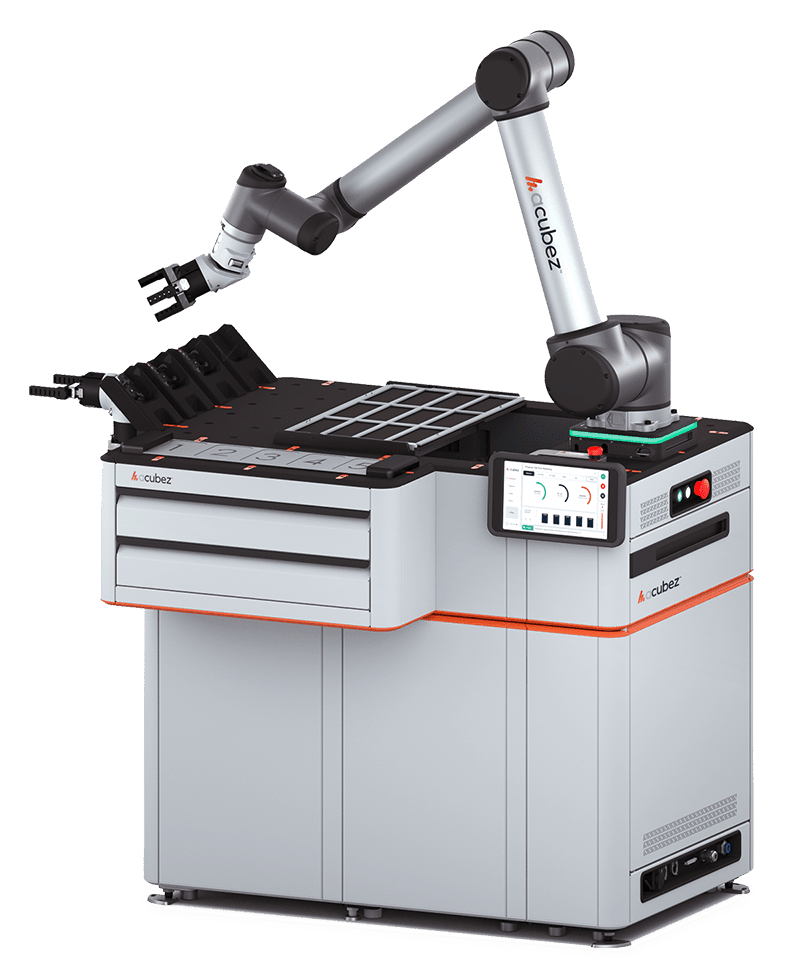

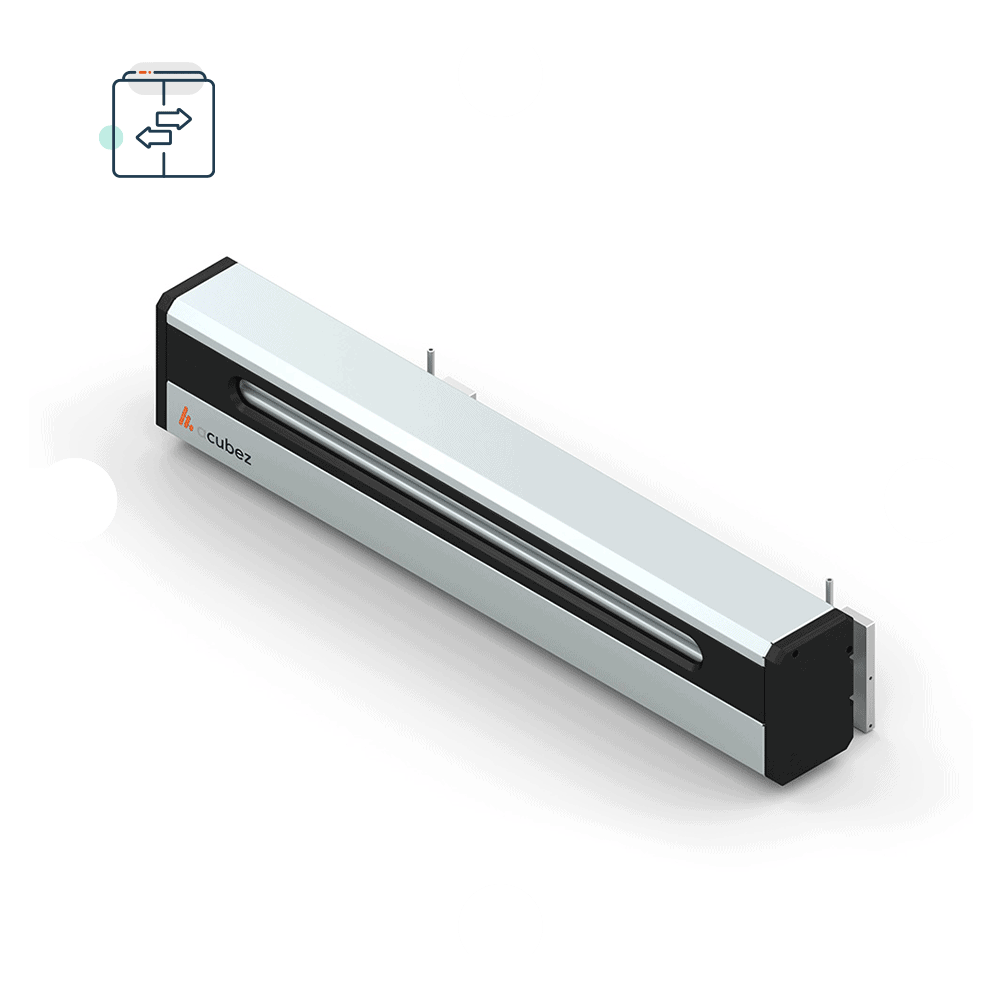

This flexible and modular end-to-end solution is capable of loading and unloading multiple trays with uninterrupted workloads. The LiftCube 600 and StorageCube 600 enable automated transport of raw materials and final workpieces. Cobot automation for CNC machines dramatically increase efficiency and productivity.

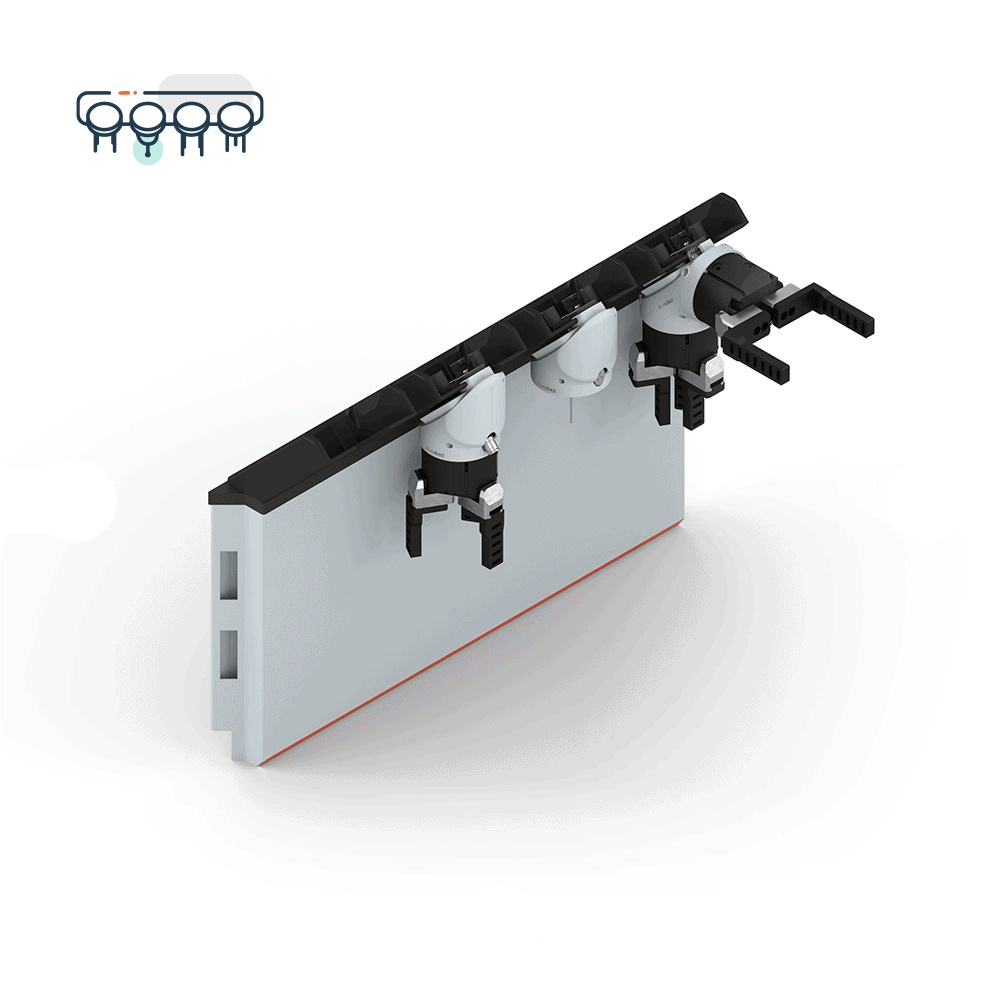

Included as a standard end of arm tooling gripper is the acubez™ Dual Gripper providing accelerated operation and flexibility for gripping both raw materials and finished workpieces simultaneously and benefit from lights out and unmanned machining.

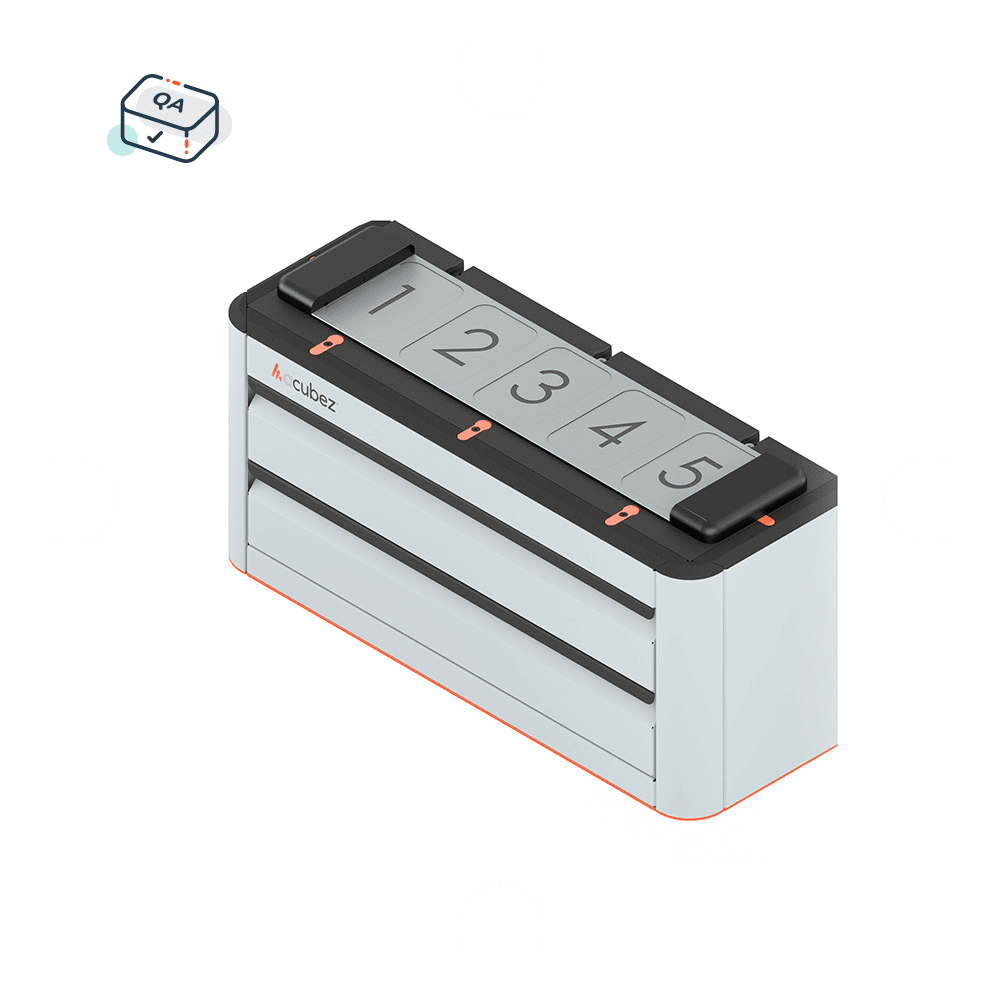

Inclusion of the QaCube and GripperCube equip the acubez™ 1400+ extended capacity configuration to optimize OEE.

- Fits best for large manufacturing lots / space with low mix

- Increase productivity with automated milling machine, mill-turning, CMM, laser marking machine and more pick and place applications