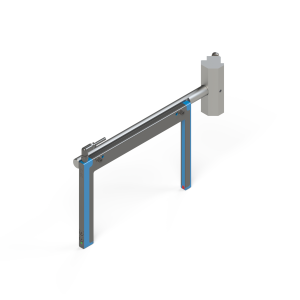

PalletCube Max

Outfitted with the proprietary acubez Self-Identification System (SIS™), the PalletCube Max offers a seamless plug & play experience through modular connectivity. This currently patent-pending module empowers acubez customers, offering them the ability to incorporate pallet handling features, facilitating expansion or retrofitting of their existing systems. Optimized to handle high capacity of up to 40 pallets, the PalletCube Max unlocks unprecedented possibilities. With the capability to interconnect multiple PalletCube Max modules, a single system can cater to enhanced storage, accommodating 120 pallets and more.

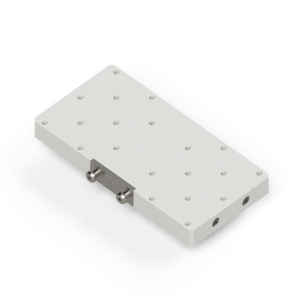

ControlCube

Cobot Arm: UR5 / UR10

StorageCube 600

Storage trays: 5 trays

Acubez™ UR5-CB3 Pneumatic-Base kit

Acubez™ Touch kit

Acubez IO Connection kit for Tended Machine

Acubez Calibration-Probe EOAT

Acubez Single 2F Gripper

Calibration-Probe accessories kit

2F Grippers Standard accessories kit

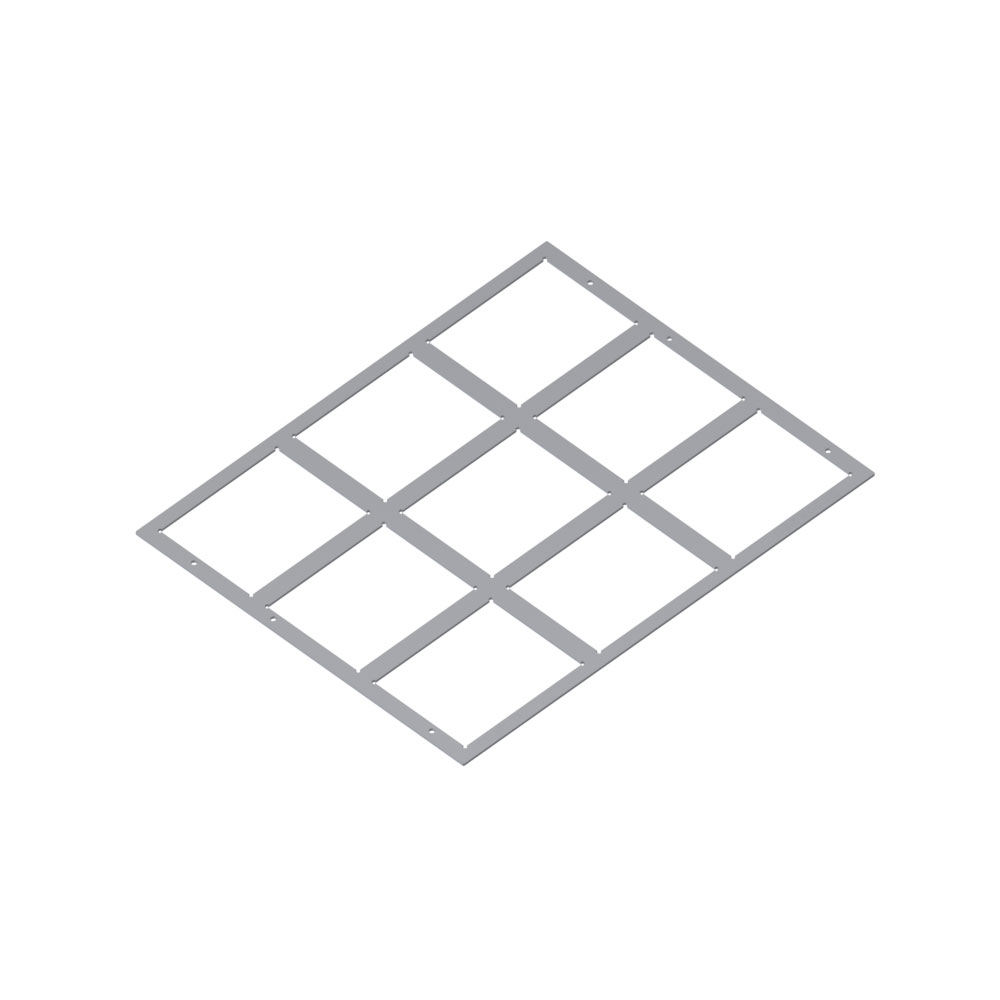

Table-GRID 600-R-3x3 size 148x115

Overview

Compatible modules and extensions

Use Cases

Downloads

- acubez™ modules brochure

- acubez™ ControlCube Datasheet

Modular Automation Benefits

Unprecedented flexibility

The modular, “LEGO-like” concept of the acubez™ automation solution allows manufacturers to keep up with ever-changing demands!

ROI: 12-18 months

Maximize your return on investment: automate with lower risk, lower cost, quick deployment, higher productivity and faster ROI

Plug & Play

Intuitive - zero programming

Within minutes any CNC machine operator can set up the automated machine tending processes for accurate operation and highly complex designs and positioning requirements.