Automated Machine: Doosan T4000L

Automation requirements

Machine tending solution for high precision CNC parts, high-mix, low-volume production

Installed Acubez™ platform & modules

Acubez™ 1000 including LiftCube, StorageCube, GripperCube, QaCube and DoorCube

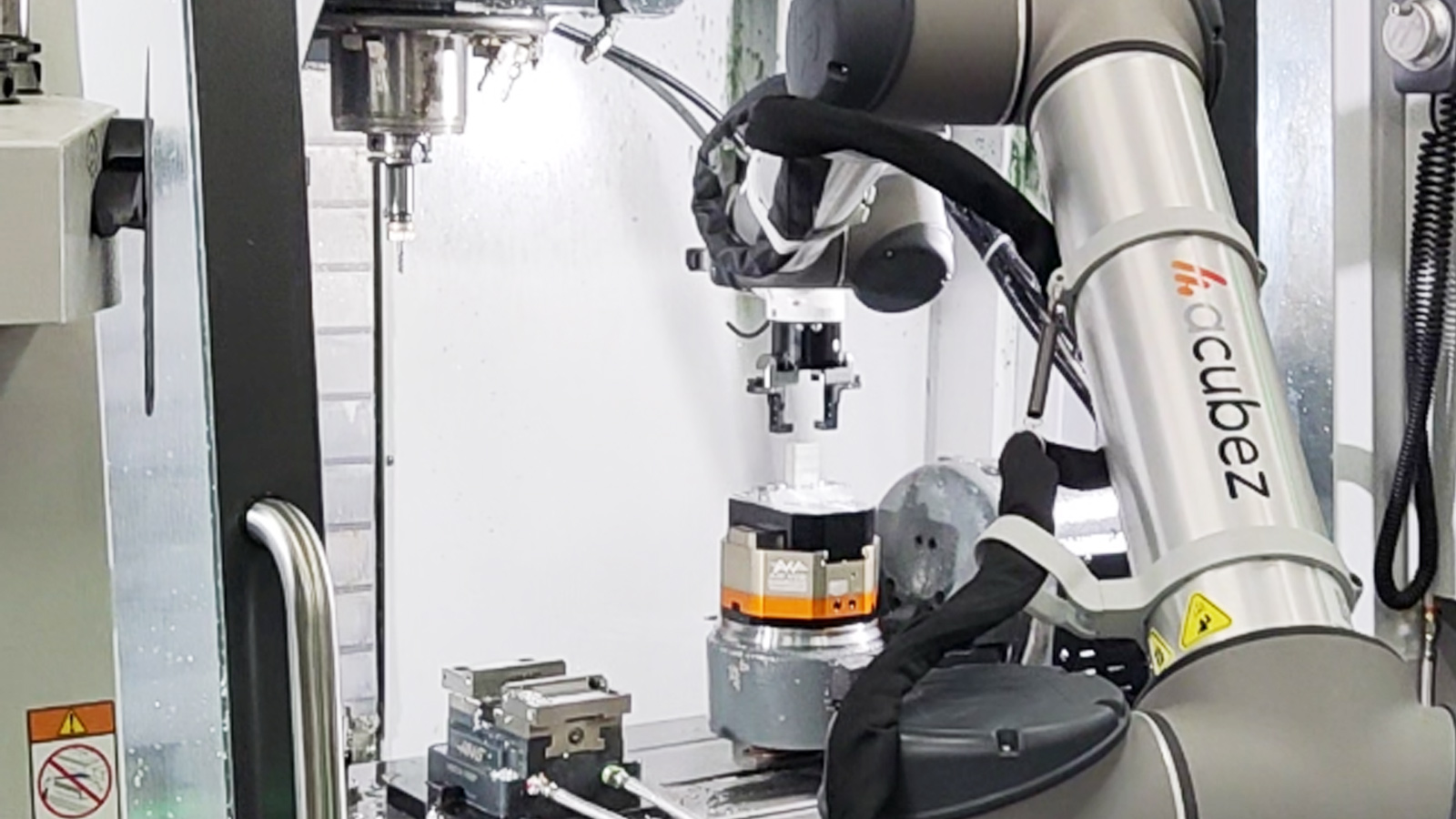

Automated Machine: Okuma MU-400V Ⅱ

Automation requirements

Machine tending solution for high-precision and complex parts for the high-tech, medical, and aerospace industries

Installed Acubez™ platform & modules

Acubez™ 800 and Acubez™ 1000 including LiftCube, StorageCube, GripperCube, QaCube, DoorCube, Safety add-ons

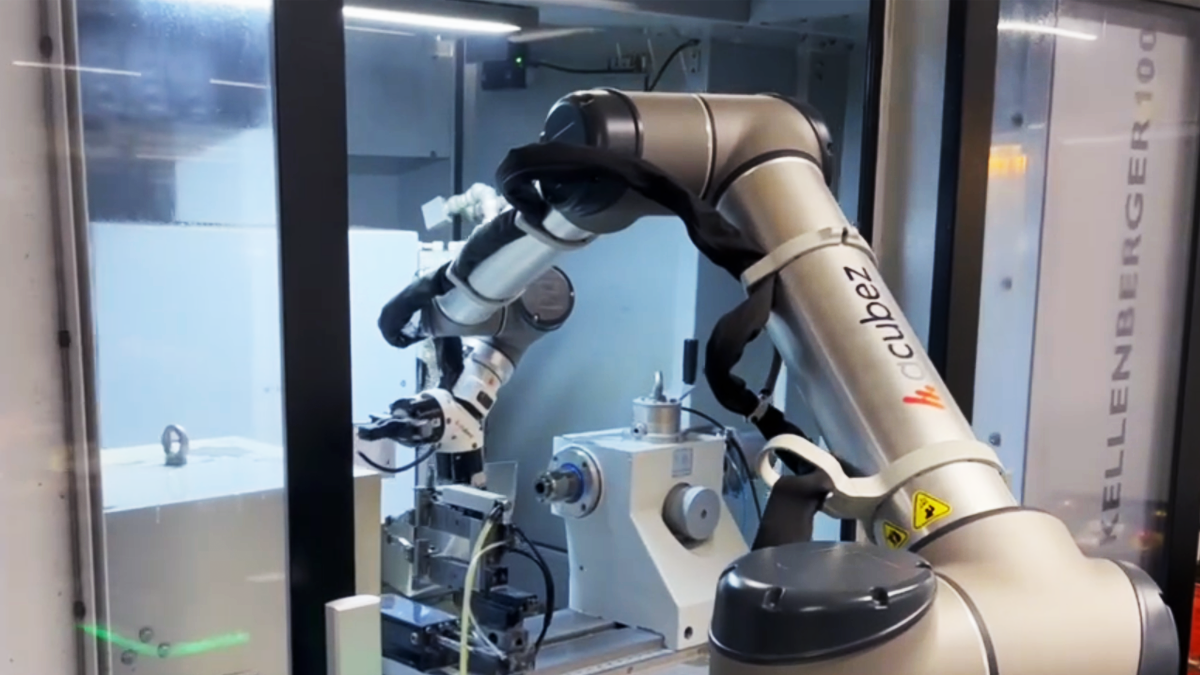

Automated Machine: Kellenberger® 1000

Automation requirements

A complete flexible system that allows fast setup of new jobs and is easy to use

Installed Acubez™ platform & modules

Acubez™ 800 with special grid for radial parts positioning and safety laser scanner

Automated Machine: LASIT TowerMark X

Automation requirements

Fully automate a laser marking machine which was operated manually, including an automatic door opener.

Installed Acubez™ platform & modules

Acubez™ 1000+ including LiftCube and DoorCube with acubez™ vacuum grippers

Automated Machine: Dea Global Silver (CMM)

Automation requirements

Turning a manually operated CMM into an unattended, testing center automatically perform the quality measurements of 100rds of parts.

Installed Acubez™ platform & modules

Acubez™ 1400 including LiftCube and acubez™ dual gripper (EOAT)

Automated Machine: Haas VF-2SSYT

Automation requirements

Machine tending solution for high-precision and complex parts for the high-tech, medical, and aerospace industries

Installed Acubez™ platform & modules

Acubez™ 800 (customized) including LiftCube, StorageCube, DoorCube, Alignment-jig (add-on)