Company

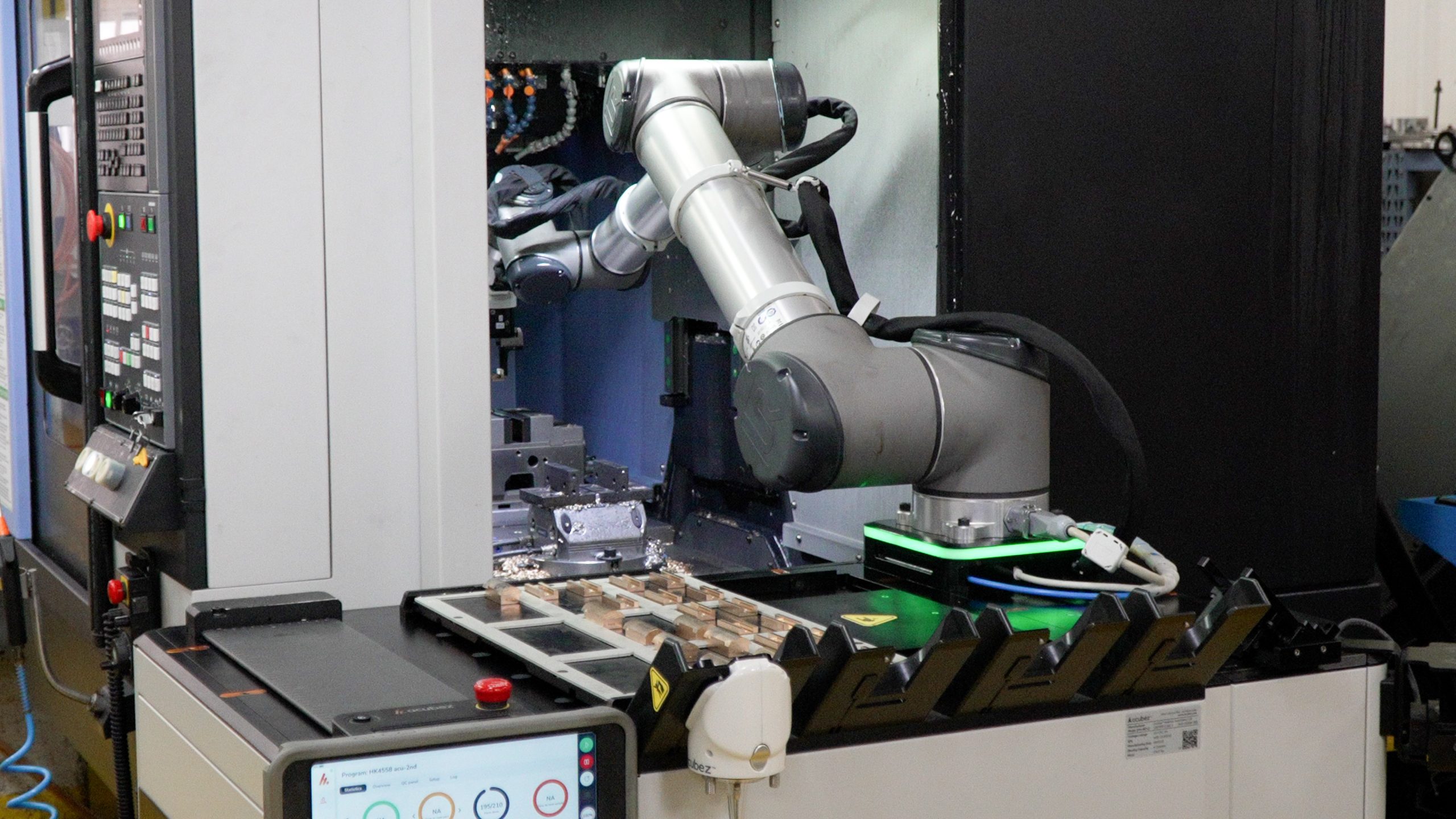

Automated CNC Machine

DN Solutions Milling Machine –

Doosan T4000L

Industry

Aerospace, Hightech

Hands-on CNC machining automation

“We quickly realized that the Acubez system was specifically designed and optimized for operating machining machines,” shares Immanuel Zahn, Operations Manager at Beth-El Industries. The metalworking team feels understood and supported by the automation solution, as praised by Simeon Weidner, Head of Machining Department: “You can simply tell that someone had machine operators like us in mind.” The experienced HMLV specialists have relied on Acubez for over half a year now and can no longer envision production without the modular automation solution.

Beth-El Industries is a part of the Beth-El Group and has been a supplier to customers worldwide since 1974. As a leading corporate group in air filtration and climate systems manufacturing, Beth-El operates modern factories with high demands for effectiveness and efficiency. This includes specialized CNC metal processing facilities to cater to the high demand for parts required for Beth-El systems within the group.

High-Mix-Low-Volume Production with Increasing Demand and Labor Shortage

The challenges faced by Beth-El Industries’

metalworking division are far from unique and have become the norm in manufacturing. The goal of delivering quickly and efficiently while maintaining consistent quality in the face of rising demand necessitates additional personnel and night shifts. However, skilled labor is scarce, often resulting in orders being outsourced, as was the case at Beth-El in the past.

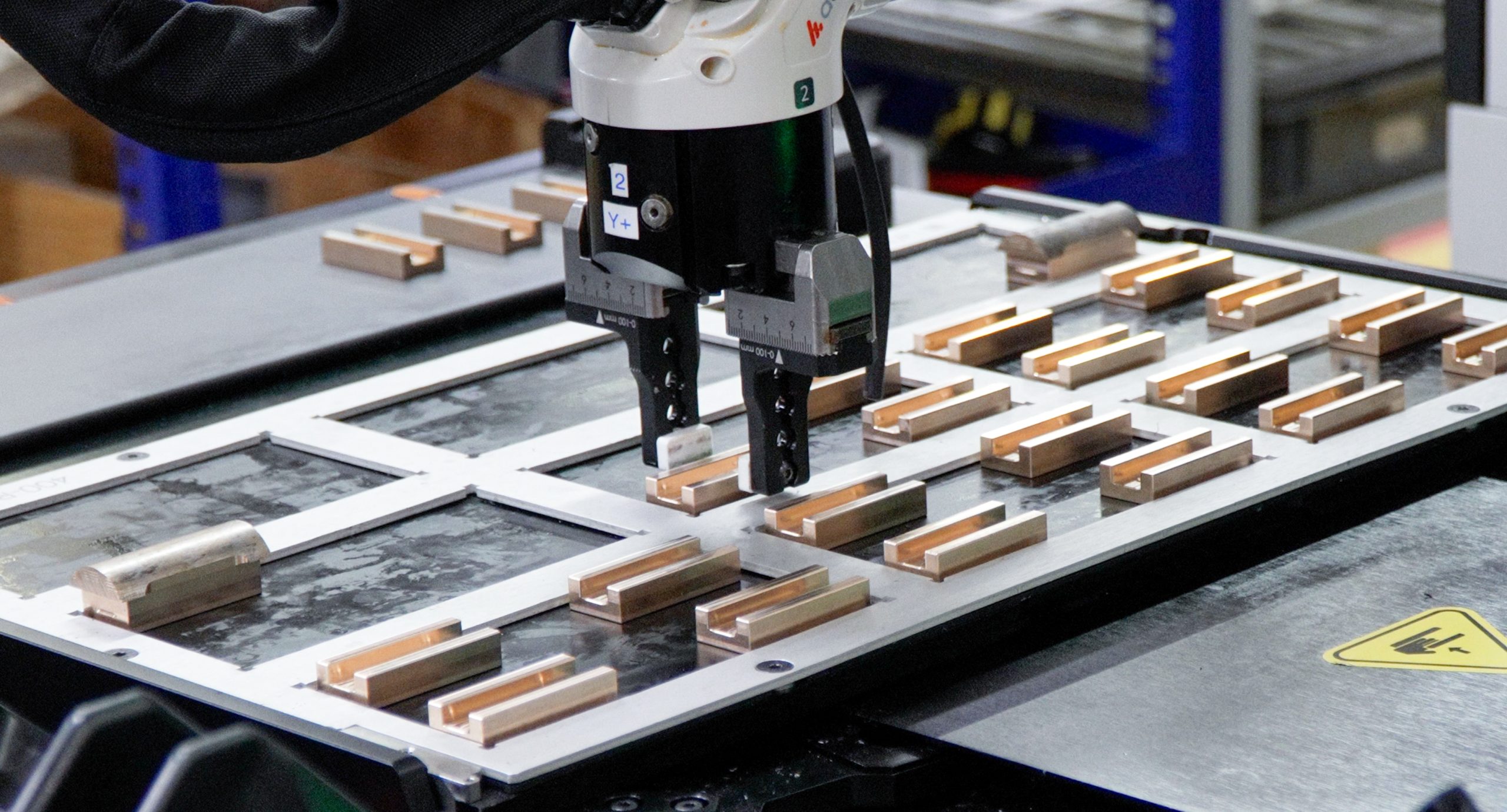

The classic HMLV (High Mix Low Volume) production

principle further complicates the situation. A wide variety of items (High Mix) are typically required in small quantities (Low Volume), demanding the highest flexibility and care in manufacturing. At Beth-El Industries, this results in the production of hundreds of different products with unique part numbers, each needing to be produced in quantities of 2 to 1,000 units within a short time frame.

Many Challenges, One Solution: Acubez Offers Tailored Modularity

The CNC machining-focused division of the Beth-El

Group had spent an extended period intensely exploring various automation systems, meticulously examining their features and functions. After finding that one targeted system could largely meet the requirements of Beth-El Industries, Acubez appeared on the scene and opened up new possibilities.

“Although Acubez’s modular solution entered the picture relatively late, it convinced us all the more quickly,” says Immanuel Zahn, Operations Manager. “It was immediately clear that Acubez had substantial depth, developed directly from manufacturing and optimized specifically for CNC technology and operating machining machines.”

Even after successful installation and commissioning within a matter of days, the Beth-El plant’s workforce on the shop floor felt an immediate alignment with the system. Simeon Weidner reports:

“With the user-friendly software, my colleagues and I can set up the different products in a maximum of half an hour and adapt them flexibly in a very short time. My personal record is 6 minutes.”

Acubez Functionality and Features Revolutionize the Metalworking Operation

The introduction to the Acubez solution was marked by several “Aha!” moments for the metalworking team.

“Features such as repositioning parts or intuitively setting up clamping devices using the 3D probe impressed us immediately. Features like integrated automatic air-blow cycles for chip removal also demonstrate that this system draws heavily from practical experience and genuine expertise from manufacturing,” reports the convinced department head after the first few months with Acubez.

Over the course of more than half a year, the modular automation solution has already proven its worth at Beth-El Industries – and has become indispensable for both senior professionals and experienced

and learning workers. Through unmanned night shifts, the operation gained a 60% increase in spindle processing time. The intuitive system can be configured and operated without programming knowledge, allowing Beth-El Industries to set up more than 160 different programs in just 7 months.

Interaction of Mechanics, Sensors, and Software is “Simply Ingenious”

A particular advantage for HMLV component production is the ability to stack material on a tray. This enables the processing of usually small quantities much faster and more flexibly. With various grippers and fingers, workpieces of different sizes and shapes can be quickly set up. The Beth-El production also benefits from the capability of the Acubez program to set up subsequent orders during ongoing part production.

Different tasks can be prepared on each floor within the lift.

“The combination of mechanics, sensors, and software is simply ingenious,” emphasizes Simeon Weidner. The department head is especially impressed by “ZERO Programming,” which allows even

novices without programming knowledge or experience to smoothly setup the 6-axis robotic Acubez system. The team is equally convinced by the automatic calculation of the cobot’s kinematics, enabling the automation system to be quickly and easily set up for new parts.

A Win on All Levels

Weidner provides a consistently positive conclusion, also on behalf of his shop floor colleagues: “The Acubez system definitely exceeded our expectations. It became evident shortly after implementation that investing in a truly flexible system is justified even for smaller batch sizes.” Operations Manager Immanuel Zahn can only underline his employees’ satisfied summary: “After this positive experience, I now know how simple and simultaneously effective automation can be to implement.

Even though we initially had a lot of respect for this step, we actually had no concerns about the automation process with Acubez.” The Operations Manager sees the focus on essentials as a particularly valuable aspect: “As manufacturers, we can once again fully concentrate on our core competencies – optimizing and stabilizing manufacturing processes – into which the automation system seamlessly integrates with minimal time and effort.”

Solution Competence Across the Board

The case study of Beth-El Industries is just one aspect of Acubez’s high solution orientation directly from real-world practice. The specialist in modular production automation presents various application examples here and reference projects.

Based on the experience of successfully implemented system solutions, Acubez customers can report a payback period of only 9 to 12 months – a calculation that also applies to the production automation at Beth-El Industries.